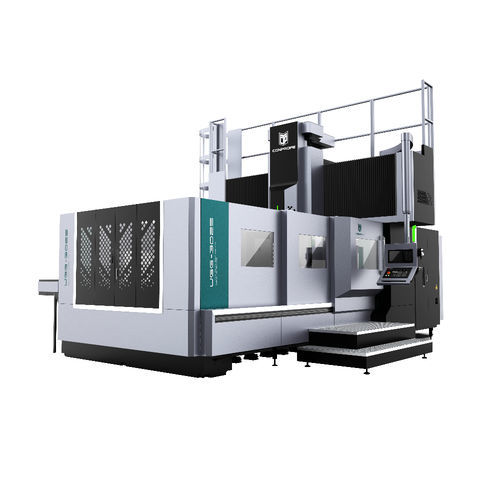

Gantry CNC machining center UGG-30255-axisverticalBT 50

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- gantry

- Spindle mount

- BT 50

- Number of tool stations

- 24 tools

- Other characteristics

- high-performance, high-productivity, ultrasonic

- X travel

3,000 mm

(118.11 in)- Y travel

2,900 mm

(114.17 in)- Z travel

1,000 mm

(39.37 in)- Rotational speed

8,000 rpm

(50,265 rad.min-1)- Power

50 kVA

(67.98 hp)- Work feed X-axis

10 m/min

- Work feed Y-axis

10 m/min

- Work feed Z-axis

10 m/min

- Table load capacity

10,000 kg

(22,046 lb)- Tool weight (max)

18 kg

(39.7 lb)- Positioning accuracy

Max.: 0.003 mm

(0.00012 in)Min.: 0.002 mm

(0.00008 in)- Repeatability

Max.: 0.015 mm

(0.00059 in)Min.: 0.002 mm

(0.00008 in)- Weight

40,000 kg

(88,184.9 lb)- Overall length

8,295 mm

(326.6 in)- Overall width

5,267 mm

(207.4 in)- Overall height

5,500 mm

(216.5 in)

Description

Features:

1.Intelligent Ultrasonic Machining System developed by Conprofe to tackle the challenges in machining hard-to-cut materials

2.Supercritical Carbon Dioxide (ScCO2) Cryogenic Cooling System and MQL Cooling System available for clean machining

3.Four structures are available (movable beam / movable beam moving column / fixed beam / fixed beam movable column)

4.X-axis travel range of 2~26m and Y-axis travel range of 1.6~9m for medium and large parts machining

5.Z-axis travel range of 0.8~2m with large space for large workpiece machining range

6.World-Class A/C swivel heads

7.Fully enclosed protection against dust and explosion available

8.Applicable to honeycomb materials, carbon-fiber reinforced plastics and non-ferrous metals

Case Sharing:

1.Nomex Honeycomb Material Machining

Machining Effect: burrs reduced by 90%; Less force on the surface, no collapse

2.CFRP Aircraft Wing Plate Machining

Machining Effect: machining efficiency up by 50% and burrs reduced by 40%

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Conprofe machining center

- Conprofe vertical machining center

- Conprofe 3-axis machining center

- Conprofe precision machining center

- CNC milling machine

- Conprofe 5-axis machining center

- Vertical CNC milling machine

- Conprofe high-precision machining center

- 3-axis CNC milling machine

- Conprofe rigid machining center

- Conprofe high-performance machining center

- Conprofe gantry machining center

- Conprofe high-rigidity machining center

- Conprofe milling machining center

- Conprofe high-productivity machining center

- Conprofe column type machining center

- Conprofe cutting machining center

- Conprofe aluminum machining center

- Conprofe machining center with pallet changer

- Precision CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.