- Products

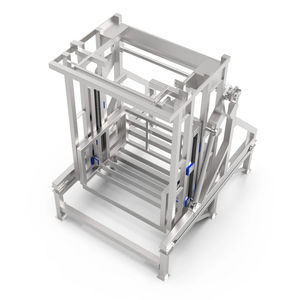

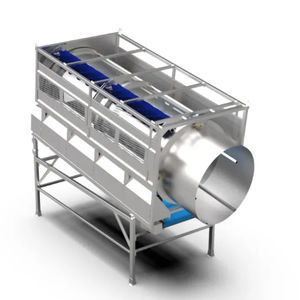

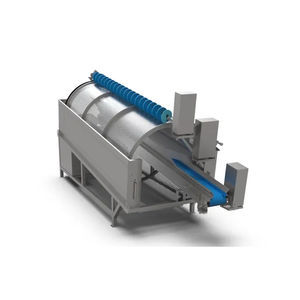

- Green beans cluster remover

- Constructie Bruynooghe N.V.

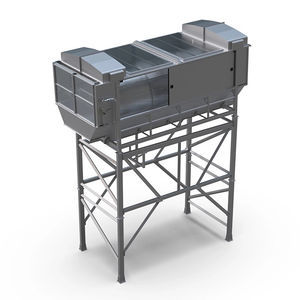

Green beans cluster remover drum

Add to favorites

Compare this product

Characteristics

- Applications

- green beans

- Type

- drum

Description

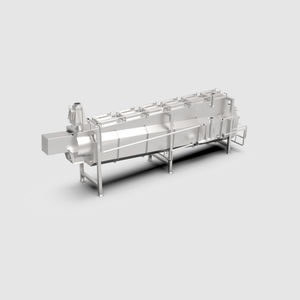

A CB decluster drum is very accessible for maintenance and inspection. This machine separates bean bunches into individual beans (+ already partially topped).

Construction made of sandblasted stainless steel 304.

Compartments with toothed dividers and shaving disks.

Knife bars with triangular blades.

FDA approved free-running brush.

Spray tube for extended blade and segment life.

Housing with sliding doors, input and output hopper.

Central lubrication unit, drum supported by PU and retention wheels.

SEW motor-reductors (steel drive chain and sprockets).

Drum built at an angle.

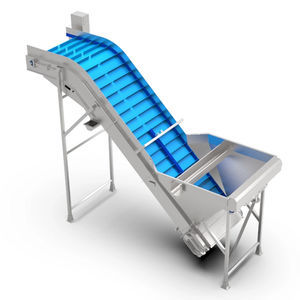

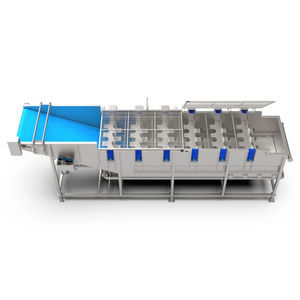

A decluster drum is deployed in a cascade together with a snipper and possibly also a UBR (unsnipped bean remover). Distribution shakers distribute the product flow over the different de-tumblers so that their capacity can be used as efficiently as possible.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.