- Products

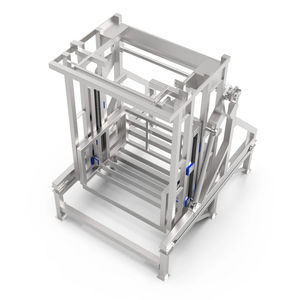

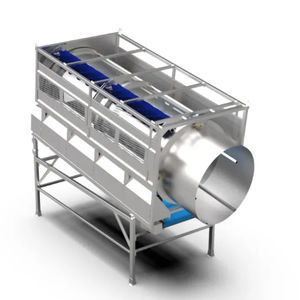

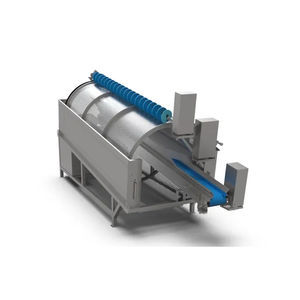

- Vegetable destoner

- Constructie Bruynooghe N.V.

Vegetable destoner for fruit

Add to favorites

Compare this product

Characteristics

- Product handled

- for vegetables, for fruit

Description

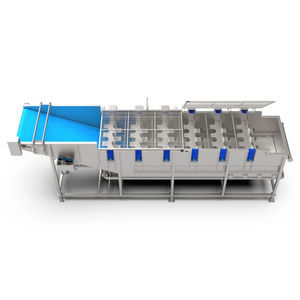

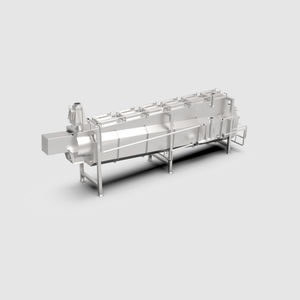

A robust stainless steel overflow destoner removes heavy impurities and foreign particles from the product flow in a product-friendly way.

Construction made of sandblasted stainless steel 304.

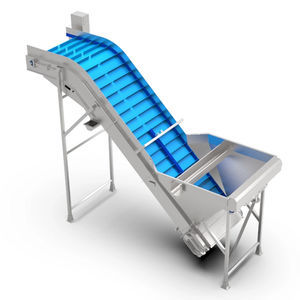

Built-in conveyors for separate disposal of product and waste:

Open structure

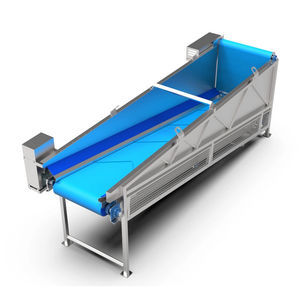

Zigzag

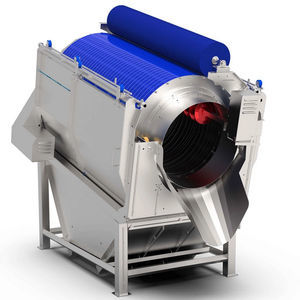

Rubber belt

Built-in cleats

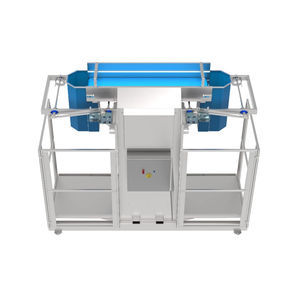

Impeller for product propulsion.

Various inspection doors for maintenance and cleaning.

Overflow gutter with purge pipe.

Valves for filling and emptying.

Powered by motorreductor SEW.

By conveying the product from the tank via a gooseneck elevator belt, the drop height is reduced to prevent the product from breaking.

The impeller is used to create an upward water flow so that the product out of the tank reaches the product conveyor, while heavy contaminants sink and are discharged by the waste conveyor.

Options:

Curved cleats.

V-shaped tire scraper.

Funnel.

Automated valves.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.