- Packing - Handling - Logistics

- Conveying

- Flexible conveyor belt

- Continental Industry Contitech

Tubular conveyor belt CONTI® PIPE flexiblefabricindustrial

Add to favorites

Compare this product

Characteristics

- Type

- tubular, flexible

- Material

- fabric

- Sector

- industrial

- Tolerance

- high-resistance

- Width

Min.: 600 mm

(23.62 in)Max.: 3,200 mm

(125.98 in)

Description

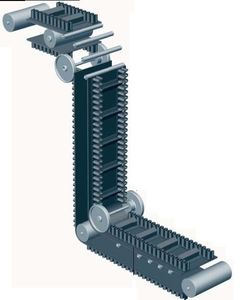

Enclosed conveyor systems for especially tight curves and high productivity

The CONTI® PIPE pipe conveyor belt differs from a conventional, troughed belt in its design and the splicing technology used, it is used to perform special conveying tasks.

Mining and industrial applications often require relatively large inclines and tight curves in confined spaces and at high mass flow rates. The specific features of modern pipe belt conveyors include: no transfer points, no material spillage along the conveyor route, and tight 3D curves, which allow them to be adapted perfectly to the landscape. Pipe belt conveyors save space thanks to their compact design and the fact that they are able to navigate steep conveyor angles of up to 30°.

Design and function of the pipe conveyor system

At the material feed point, the conveyor belt is troughed and is fed like a conventional conveyor belt. Beyond the material feed point, the conveyor belt is formed into a closed belt pipe by specially configured finger rollers. Further idlers set along the conveyor route guarantee that the belt is kept closed. As a result, the material being conveyed remains protected by the closed belt system.

At the end of the belt run, the finger rollers are configured in such a way that the closed belt is opened and adopts a flat shape at the pulley. The material being conveyed can then be discharged in the same way as with conventional belt systems.

Catalogs

CONTI® PIPE

16 Pages

Other Continental Industry Contitech products

Conveyor belt systems

Related Searches

- Conveying belt

- Plastic conveyor belt

- Industrial conveyor belt

- Flexible conveyor belt

- High-resistance conveyor belt

- Rubber conveyor belt

- Textile conveyor belt

- Conveyor belt for the chemical industry

- Heavy-duty conveyor belt

- Abrasion-resistant conveyor belt

- Polyester conveyor belt

- Oil-resistant conveyor belt

- Reinforced conveyor belt

- Wear-resistant conveyor belt

- Steel conveyor belt

- Steel cord conveyor belt

- Nylon conveyor belt

- Corrosion-resistant conveyor belt

- Sidewall conveyor belt

- Hinged belt conveyor belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.