- Packing - Handling - Logistics

- Conveying

- Rubber conveyor belt

- Continental Industry Contitech

- Products

- Catalogs

- News & Trends

- Exhibitions

Rubber conveyor belt POCKETLIFT® hinged beltindustrialoil-resistant

Add to favorites

Compare this product

Characteristics

- Material

- rubber

- Pattern

- hinged belt

- Sector

- industrial

- Tolerance

- oil-resistant

- Other characteristics

- reinforced, steel cord

- Width

Max.: 1,400 mm

(55.12 in)Min.: 500 mm

(19.69 in)

Description

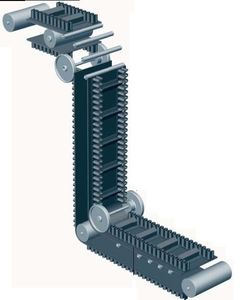

The POCKETLIFT® system is the most recent innovation in the field of steep incline and vertical conveying for the bulk materials handling industry.

Based on the FLEXOWELL® technology and the high capacity bucket elevator, the POCKETLIFT® system was developed for deep shaft underground applications in the mining and tunneling industry and achieves lifting heights of up to 800 m.

Best choice for continuous conveying

POCKETLIFT® technology is offering mining engineers and operators the possibility of achieving a continuous mass flow over a lift height of several hundred meters, which brings with it a number of additional benefits, such as:

Reduced energy consumption

Small shaft diameter

Quick installation

Low maintenance costs

No underground bunker system required

Lightweight steel structure for feeding section and headframe

Environmentally friendly

No mechanical parts in the vertical shaft

Technical details

With POCKETLIFT®, power transfer is achieved by means of two narrow steel cord belts connected together with rigid triangular cross bars. The material to be conveyed is fed into the fabric reinforced rubber pockets, which are bolted to the center of the cross bars. These bars also have a guiding function. All three elements can be mounted and removed separately and can be installed on site.

The standard POCKETLIFT® Type III achieves capacities of up to 1500 m3/h and lift heights of up to 800 m, while the new generation POCKETLIFT® Type II was developed for high capacities up to as much as 4000 m3/h. Different pocket widths for both systems enable them to be tailored to precisely meet customer requirements.

VIDEO

Catalogs

Other Continental Industry Contitech products

Conveyor belt systems

Related Searches

- Conveying belt

- Plastic conveyor belt

- Industrial conveyor belt

- Flexible conveyor belt

- High-resistance conveyor belt

- Rubber conveyor belt

- Textile conveyor belt

- Conveyor belt for the chemical industry

- Heavy-duty conveyor belt

- Abrasion-resistant conveyor belt

- Polyester conveyor belt

- Oil-resistant conveyor belt

- Reinforced conveyor belt

- Steel conveyor belt

- Wear-resistant conveyor belt

- Steel cord conveyor belt

- Nylon conveyor belt

- Corrosion-resistant conveyor belt

- Sidewall conveyor belt

- Hinged belt conveyor belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.