- Packing - Handling - Logistics

- Conveying

- Flexible conveyor belt

- Continental Industry Contitech

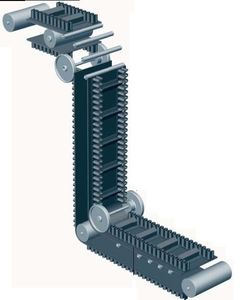

Flexible conveyor belt SICON® industrial

Add to favorites

Compare this product

Characteristics

- Type

- flexible

- Sector

- industrial

- Width

650 mm, 800 mm, 1,000 mm, 1,200 mm, 1,400 mm

(25.59 in, 31.5 in, 39.37 in, 47.24 in, 55.12 in)

Description

Clean, safe and able to negotiate curves of up to 180°

The SICON® conveyor belt remains closed from the feeding point through to the discharge point. It is therefore able to meet particularly stringent requirements with regard to its ability to negotiate curves, its cost-efficiency and its environmental compatibility.

SICON® conveyor belts offer extreme flexibility when it comes to designing the layout of the line, allowing them to be perfectly tailored to any environment. They can cope with corners and edges without the need for additional transfer points. Cornering radii of less than a meter can be achieved, making it possible to establish serpentine routing, which is often required to cope with major altitude differences over very short distances.

Construction

Vertical guide pulley

Two steel cords vulcanized into the belt with a common axis to enable extremely short radii

Support pulleys tilted to close the belt

Two profiles led by the guide and support pulleys

Pouch-shaped section of belt for carrying the material being conveyed

Properties

Copes well with steeply rising topography in narrow areas

Eliminates the need for transfer points thanks to its excellent ability to negotiate curves

Non-polluting as the belt is closed on the return trip

Allows for a two-way conveyor system: belt can be loaded in both directions; varying routing possible for trip out and back

Prevents dust emissions

Protects sensitive materials

Lightweight and flexible, easy to install; self-centering between guide pulleys and support pulleys

Catalogs

Conveyor Belt Solutions

28 Pages

Other Continental Industry Contitech products

Conveyor belt systems

Related Searches

- Conveying belt

- Plastic conveyor belt

- Industrial conveyor belt

- Flexible conveyor belt

- High-resistance conveyor belt

- Rubber conveyor belt

- Textile conveyor belt

- Conveyor belt for the chemical industry

- Heavy-duty conveyor belt

- Abrasion-resistant conveyor belt

- Polyester conveyor belt

- Oil-resistant conveyor belt

- Reinforced conveyor belt

- Wear-resistant conveyor belt

- Steel conveyor belt

- Steel cord conveyor belt

- Nylon conveyor belt

- Corrosion-resistant conveyor belt

- Sidewall conveyor belt

- Hinged belt conveyor belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.