- Production Machines

- Other Manufacturing Equipment

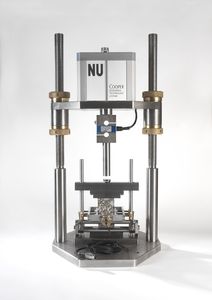

- Large roller compactor

- Cooper Research Technology

Large roller compactor CRT-RCENLD-III

Add to favorites

Compare this product

Characteristics

- Type

- large

Description

Roller compaction is the laboratory method that most closely simulates on-site compaction. The machine can be configured to operate with a single or twin wheels depending on the mould size. The wheels track the surface in overlapping wheel-paths using sequences specified in EN 12697-33 or custom sequences designed by the user. The base of the mould is incrementally raised by a precision jacking system and the system is tracked to keep it level with the top of the mould. Compacted slabs can be from 50 to 150mm thick. 500 x 180mm slabs are usually wheel tracked in the Cooper Technology Large Wheel Tracker, whilst 600 x 400mm slabs are normally cut to produce trapezoidal or prismatic specimens for fatigue, modulus tests and Duriez test.

Catalogs

Product catalogue

134 Pages

Other Cooper Research Technology products

ASPHALT TESTING

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.