- Packing - Handling - Logistics

- Conveying

- Pneumatic conveying rotary valve

- Coperion K-Tron GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

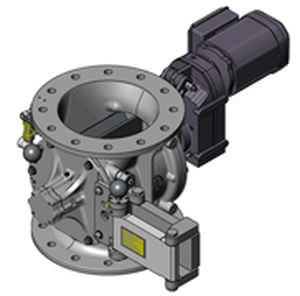

Pneumatic conveying rotary valve ZVDround-flange

Add to favorites

Compare this product

Characteristics

- Applications

- for pneumatic conveying

- Type

- round-flange

Description

The K-TRON ZVD series rotary valves serve as discharging valves for irregular fine and coarse grained products, such as regrind. They can also be used for regular pellets, that request increased purity levels, due to reduced dead zones that help prevent accumulation of residue. They are made via special inlet geometry principle, offering easy of handling and usability for heavy-duty industrial services. They show quality performance for differential pressures up to 1.5 bar, and temperatures up to 100 °C (212 °F). They are highly shock resistant (10 bar of pressure), contain a rotor with 10 blades, with open end and flat tips, and offer high filling effectiveness due to internal leakage gas venting. The inlet flange is round and drilled, per DIN PN 10 or ANSI 150 lbs. They also contain two NBR lip seals with labyrinth rings, that offer preparation for seal purge. They are also completely CE compliant.

Other Coperion K-Tron GmbH products

Aerolock™ Rotary Valves

Related Searches

- Feeder

- Weighing scale with separate indicator

- Solid dispensing system

- Dosing unit for the food industry

- Pneumatic conveying system

- Rotary valve

- Bulk feeder

- Gravimetric dosing unit

- Diverter valve

- Pneumatic conveying rotary valve

- Continuous feeder

- Compact feeder

- Powder pneumatic conveying system

- Motorized feeder

- Industry feeder

- Round-flange rotary valve

- Dense phase pneumatic conveying system

- High-precision feeder

- Storage hopper

- Aspiration pneumatic conveying system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.