- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

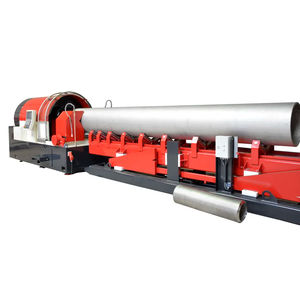

Stationary pipe cutting and beveling machine BEAVER 16 CB

Add to favorites

Compare this product

Characteristics

- Options

- stationary

Description

The Copier Beaver CB Series is a beveling and cutting machine in one; beveling and cutting are performed in one process flow. This makes the machine not only time-efficient but also space-efficient while minimizing the internal transportation of the pipes. As the machine allows you to do multiple operations there is no need for separate cutting and beveling machines.

The Beaver CB is a CNC-controlled machine that is able to create almost any welding type such as J-prep, V-bevel, tapering, facing, and squaring without changing tools. The machine can bevel pipes with unlimited wall thickness and provides high-quality cuts and bevels continuously. Its user-friendly design and interface allow an operator to function after 2 days of training. The Beaver CB is customizable to meet your specific production requirements. Moreover, the machine can be integrated into an automated production line.

Wide range of machining and bevel options

High variation of diameter range over the Beaver CB Series (OD 1" - 56"). Almost any welding type can be created (J-bevel, V-bevel, tapering, facing, squaring) without changing tools.

Long life span

Solid and durable design ensures a long product life span with low-maintenance.

Time efficient

Cutting and beveling in one process flow. All welding types can be created with one tool, with no need for adjustments. The CNC system allows you to perform preset shapes automatically.

High repeatability

Provides high-quality cuts and bevels continuously.

Space efficient

Instead of having two machines for cutting and beveling individually, the compact design allows you to do multiple operations on one machine. It saves space in your production facility.

Catalogs

No catalogs are available for this product.

See all of Copier Machinery‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.