- Products

- Catalogs

- News & Trends

- Exhibitions

Assembly line

Add to favorites

Compare this product

Description

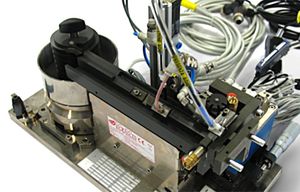

Hine with rotary table to assemble fender spring in plunger

Technical data

Speed (pieces/hour) - 5.700

Components to be assembled - 2

Product Versions - 1

Ready to Run

Start-up time - 2 hours

Ramp-up time - 2 hours

Characteristics

Main features

The main feature of the machine is its speed. The machine is able to produce 95 pz. min. To reach this aim, the following elements have been employed on the machine:

· electric resonant feeders both for the linear and the circular bowls machined with CNC selections;

· the regulators employed on the machine are all of the last generation, placed into the electric board. On the machine there is only a starting and cutting switch.

To modify the working parameter it is necessary to connect, with the pushbutton board, to the arranged socket on the electric board;

· the pick&place arms are mechanical and they are able to reach 130 strokes/ minute.

The machine is conceived to let the operator check the different assembling phases and intervene, if necessary, with promptness in case of anomaly.

The different parts of the machine are realized with standardized units by Cosberg.

The unloading station equipped with of an electric servo controlled cylinder. It lets many programmable linear and flexible positions to be obtained.

The machine equipped with an operator panel which is necessary to the man/ machine interface, to visualize the alarms and the allotted counters (nr. lots, case, good/discards).

The entire software employed on the machine is completely developed from Cosberg.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.