- Products

- Catalogs

- News & Trends

- Exhibitions

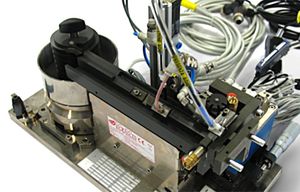

Linear assembly line testfor solenoid valve actuators

Add to favorites

Compare this product

Characteristics

- Operating mode

- linear

- Applications

- test, for solenoid valve actuators

Description

Linear machine to mount and test solenoid valve actuators

Characteristics

Main features

Monobloc frame made of welded steel to ensure easy machine transport without dismounting the units for quick start-up.

Smart and universal (for all the product versions) pallet encoding system.

Nr. 3 electric presses for the insertion of some components with ±10 micron tolerance. Thanks to a closed-loop-control system featuring linear transducers and measuring video cameras, we can guarantee these tolerances, although the components are built with 0,1 mm tolerance.

Considering the reduced dimensions of the components, all of them are fed by means of piezo-electric vibration feeders MOXMEC.

The machine features 4 video cameras, one for measuring the insertions depths, one for robot guidance, and two for controls on the assembled pieces.

There is an electric control on the solenoid to check that the coil is not interrupted and that the right solenoid is loaded on the machine.

The machine features 2 flow-rate and leak test controls of the valves.

There are 2 robots to load/unload on a tray: one robot loads the coil by means of a guiding robot, the second one is for the testing units and for palletizing the assembled product.

On the machine there is a gluing unit: the glue is UV single component. Then there is a station with a UV led lamp for polymerizing the glue.

Laser for marking the logo and the serial number on good valves.

Cosberg system for production data monitoring with graphical display of production and stoppages statistical data.

The machine can control automatically the measure systems

mounted on the machine.

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.