- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

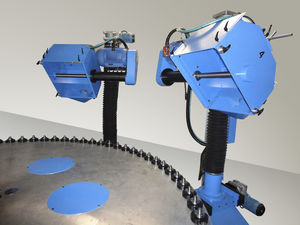

Polishing machine with rotary table TR+CNC2for metalstileautomotive

Add to favorites

Compare this product

Characteristics

- Machined material

- for metals

- Applications

- tile, automotive

- Other characteristics

- CNC, double brush, with rotary table, 7-axis

Description

The ideal solution to automatize a multi-phase polishing process with a single unit.

This double-buff CNC2 polishing unit is a further step towards the innovation and development of the already consolidated and renowned CNC polishing unit.

The combination of the characteristics of the Indexed Rotary Table with the innovative and flexible multi-axis polishing units called CNC2 allows to reduce dramatically the size and cost employing a single unit for multiple processing steps. Great for processing small batches, the double-buff CNC2 units distinguish themselves for their great flexibility and their reduced cost compared to the task performed.

The movements of each polishing unit are controlled by seven different controlled axes that can manage two different polishing heads.

The fixture, placed on the spindle can perform rotation movements as well as overturning movements that may be interpolated with those of the polishing unit.

Therefore, each station has nine controlled and interpolated axes, considering the two on the table, and the seven on the unit.

Limited expense

The price is reduced as a single unit, possessing the capabilities of two, can be bought. The unit can perform complex operations for a wide range of products with no performance limitations and with a smaller quantity of fixtures on the table, hence speeding up the set-up time of the machine.

• Great flexibility, even when managing a process that implies multiple phases

• Contained price compared to the task performed

• Rotary Table accessories and tool rack contained costs

• The great flexibility of the CNC unit allows to polish any kind of object – even complex-shaped ones

VIDEO

Catalogs

Related Searches

- Grinding machine

- Flat grinding machine

- COSMAP polishing machine

- COSMAP metal polishing machine

- Automated grinding machine

- Tool grinding machine

- Finishing machine

- Automatic polishing unit

- Grinding polishing machine

- Industrial polishing unit

- Surface polishing machine

- Finishing polishing machine

- Metallographic sample grinding polishing machine

- Polishing finishing machine

- COSMAP CNC polishing machine

- Grinding polishing unit

- Industrial finishing machine

- Metal finishing machine

- Trimming finishing machine

- Finishing finishing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.