- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

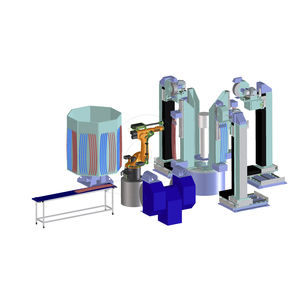

Electric rotary table TR + CNC - CNCSverticalloadingflexible

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Configuration

- vertical

- Applications

- loading

- Other characteristics

- flexible, with linishing unit, with CNC polishing unit

Description

A highly productive combination, with a great flexibility in process management and complex surface treatment

A technological evolution that combines the indexed rotary table characteristics with the innovative and flexible CNCS grinding and CNC polishing units. This solution is to consider as the first step to Lean Manufacturing.

The combination of two distinct processes, with opposed characteristics and, most importantly, the possibility to hide the loading cycle time makes this kind of machine the ultimate expression of flexibility and productive capability.

Thanks to this solution, it is possible to go through the grinding and polishing process using the indexed rotary table with the advantage of executing an entire process with hidden cycle times.

• Lean Manufacturing solution;

• High productivity rate thanks to the rotary table and hidden loading/unloading cycle times;

• CNC and CNCS polishing units flexibility, capability of grinding and polishing any kind of object, even complex-structured ones;

• Quick and certified machine set-up, granting an immediate production change;

• Programming ease thanks to a self- learning system with no need to learn any kind of machine-programming language;

• CNC and CNCS units sizing variable according to the client’s choice (from light to heavy CNC).

VIDEO

Catalogs

No catalogs are available for this product.

See all of COSMAP‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.