- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

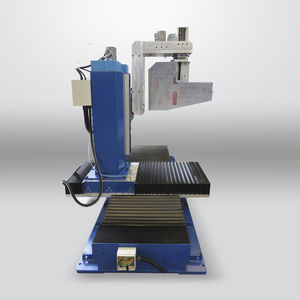

Robotic surfacing cell IRloadingunloadingfinishing

Add to favorites

Compare this product

Characteristics

- Function

- loading, unloading, finishing, grinding

- Applications

- for machine tools, for the automotive industry

Description

Thanks to special grinding units, it is possible to shift the tool needed in the process from, for example, simple grinding disks to flap wheels, to scotch-brite buffs, etc.

Furthermore, each unit is equipped with a controlled axis that allows the rotation of the entire grinding head on a 0 to 180 degrees angle, with the intent to ease and speed up the grinding process, helping the robot as it needs to reach uneven surfaces or when its own arm stands in the way.

Each unit is also mounted on a linear, controlled-axis ball screw to manage the operating pressure and to compensate the consumption of the buff, and/or to reposition the unit if required.

This way, the robot settings do not need any further modifications, as the robot itself is capable to move back and forth easing and speeding up the product processing, hence improving the productivity of the machine and its versatility.

Each robotic cell can be designed and developed with a loading/unloading automatic system according to the nature of the specific product to process: double pallet, belt conveyor system, vertical/drum loader system, just to mention a few.

Our robotic cells may be single, double or triple according to the client’s processing needs.

• High production rates thanks to the combination of multiple robot units on the same working cell;

• Enhanced flexibility thanks to grinding units that may be equipped with grinding belts, flap wheels, or scotch-brite buffs ;

• Great flexibility and movement speed thanks to the two axes each grinding unit is equipped with;

• Multiple loading/unloading system options;

• Programming easiness with self-learning system.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.