- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

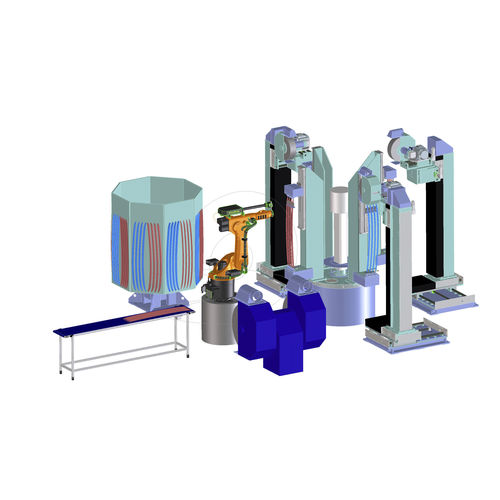

Robotic polishing cell IR + TRloadingunloadinggrinding

Add to favorites

Compare this product

Characteristics

- Function

- loading, unloading, grinding, polishing

- Applications

- for machining centers

Description

The most complete and performing solution for flexibility, process and productive capacity.

A spreading solution reassuming the concept of Lean Manufacturing and processing efficiency, plus the robot-equipped with a grinding isle and the rotary table for polishing. Two dramatically different concepts bound by one characteristic: the cycle time management. This solution is based on the idea of hiding any processing step within the same cycle time. The aim is to synchronize the fast grinding process with the slower polishing process. Each turn will deliver a grinded, polished, and therefore finished piece. The automated isle’s grinding flexibility and the rotary table’s polishing efficiency make the processing isle the best, synergic solution to optimize the production process. Each isle can be designed with an automatic loading/unloading system accordingly to the product nature: Double pallet system, belt, vertical/drum loader, just to mention some.

The automated isles can be single, double or triple according to the client’s productive necessities.

• High productivity rate thanks to the multiple robot/rotary table combination on the same processing isle;

• High process flexibility thanks to grinding units equipped with abrasive belts, flap wheels, or scotch-brite buffs and to the rotary table’s CNC polishing units

• Total autonomy for a long operational period;

• Multiple loading/unloading systems;

• Programming easiness with self-learning system.

VIDEO

Catalogs

No catalogs are available for this product.

See all of COSMAP‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.