- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

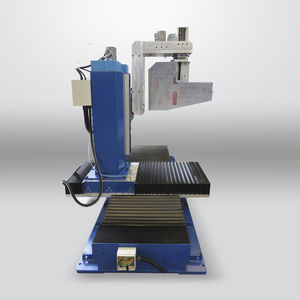

Surface grinding machine BMtoolautomaticmobile

Add to favorites

Compare this product

Characteristics

- Type

- surface

- Applications

- tool

- Control type

- automatic

- Features

- mobile

Description

The mobile bench or static bench solutions can be associated with any kind of grinding unit, from the basic ones needed to operate on a linear surface to the most complex CNCS ones.

The necessity to find a way to perform the loading/unloading task within hidden times, meaning during the simultaneous processing of the same amount of pieces, is very important for these units, too.

The static bench is to intend with the possibility to get a steady or static gripper whilst the piece moves to a different working station, or the opposite.

The grinding unit may either be equipped with a simple axis that pneumatically checks the working pressure, therefore setting the adequate contact wheel position according to the position of the currently processed piece (thanks to controlled servo-axes), or with up to nine axes that can be interpolated between themselves and the spindle/piece holder axes.

An automatic tool rack may be attached to multi-axis units, allowing the utilization of a single unit capable of switching between up to ten tools, permitting to go through an entire process without the need to shift between different units or increasing their number.

• Easiness of use.

• Hidden loading/unloading times.

• Possibility to have a single, multi-axis grinding unit with attached tool rack to complete an entire process.

• Fast and easy production change thanks to the auto-positioning.

• Easy maintenance.

• Possibility to grind multiple flat surfaces on a single piece, maintaining a high quality standard.

• CNCS grinding unit flexibility.

• Quick and certified machine set-up, thus immediate production change.

VIDEO

Catalogs

No catalogs are available for this product.

See all of COSMAP‘s catalogsRelated Searches

- Grinding machine

- Flat grinding machine

- COSMAP polishing machine

- COSMAP metal polishing machine

- Automated grinding machine

- Finishing machine

- Tool grinding machine

- Automatic polishing unit

- Grinding polishing machine

- Industrial polishing unit

- Surface polishing machine

- Finishing polishing machine

- Metallographic sample grinding polishing machine

- Polishing finishing machine

- COSMAP CNC polishing machine

- Grinding polishing unit

- Industrial finishing machine

- Metal finishing machine

- Trimming finishing machine

- Finishing finishing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.