- Robotics - Automation - Industrial IT

- Automation

- Remote control unit

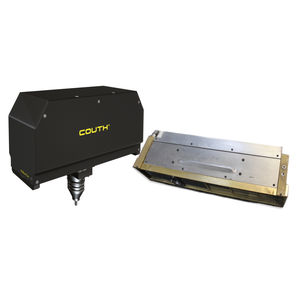

- COUTH INDUSTRIAL MARKING SYSTEMS

Remote control unit COUTHsmartboxstand-aloneprogrammable

Add to favorites

Compare this product

Characteristics

- Applications

- remote

- Other characteristics

- programmable, stand-alone

Description

• Cutting-edge modular control unit to control COUTH® dot-peen and scribe marking units.

• Increased power for COUTH® marking units, 15-20%, providing greater marking depth and/or speed, thanks to more advanced electronics.

• Autonomous control system, does not require PC to operate.

• Connection available for main communication protocols (Profibus, Profinet, Ethernet/IP, etc.).

• Possibility of remote connection.

• Simplified encasing design. Simple and optimised cover assembly and disassembly.

• Reception of diagnostics in PLCs made by the COUTHsmartbox control unit.

• Removeable and interchangeable screen, easy to place.

• Colour user interface, more intuitive.

• Interchangeable with existing hardware.

• Adjustable marking speed and depth.

• 11 input signals and 7 output signals that can be programmed for connection with controller.

• Marking on straight, tilted, arc and mirror lines.

• Marking sequential numbers and repetitions, shifts, hour, date, week, etc.

• Marking logotypes and special characters from vectoral archives, DXF, DWG and PLT/HPGL.

• Marking DATAMATRIXTM codes, both square and rectangular, as well as QR codes.

• Possibility of using and creating any font type requested by the client.

• Compression, expansion and spacing between characters, cursive and density of marking can all be adjusted.

• 40-line files and 75-character line.

• Possibility of storing up to 10,000 marking files.

Catalogs

CONTROL COUTHsmartbox

4 Pages

COUTH INDUSTRIAL MARKING SYSTEMS

32 Pages

Other COUTH INDUSTRIAL MARKING SYSTEMS products

Dot Peen Marking

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.