- Production Machines

- Other Manufacturing Equipment

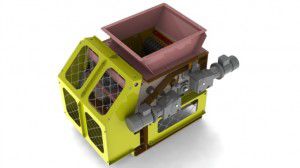

- Glass screener

- CP Manufacturing

Glass screener NEWScreenlinear vibratingfor bulk materials

Add to favorites

Compare this product

Characteristics

- Applications

- for glass

- Type

- linear vibrating

- Material

- for bulk materials

Description

CP’s Scalping Screen is positioned at the front of the sort line and separates small fiber, glass, containers and fines from large pieces of fiber. The CP Scalping Screen increases efficiency of the glass breaker by preventing “blinding”, while eliminating small containers from entering the CP NEWScreen. The Scalping Screen contributes to keeping both the fiber and container line much cleaner while increasing system capacity and lowering system maintenance. It also lowers labor costs, reducing the amount of sorters on the fiber line.

Features & Benefits:

Automatically separates small glass, fiber, containers and fines from large fiber

Unique offset elliptical pattern provides lateral agitation to free trapped material and riders

Cleaner and more marketable end-products

Increases system processing capacity

Lowers labor costs through decreasing amount of sorters needed on fiber line

Consistent spacing between discs at all points at all times prevents jamming

Bolt-in “spindle” shafts allows shafts to be removed or replaced

Waterfall design, along with clocked, elliptical discs ensure optimum agitation of material

CP Syncdrive™ uses carbon fiber timing belts rather than chain drives, eliminating the need for oilers, tensioners or adjustments, while reducing wear, maintenance and noise

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.