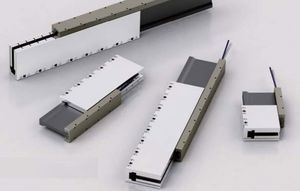

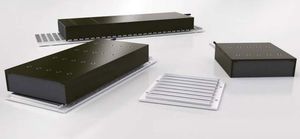

Iron-core linear motor LM-CC series aluminum framehigh-performance

Add to favorites

Compare this product

Characteristics

- Type

- iron-core

- Configuration

- aluminum frame

- Performance

- high-performance

- Force

Max.: 1,777 N

Min.: 592 N

- Power

Max.: 5,265 W

(7.158 hp)Min.: 1,755 W

(2.386 hp)

Description

Ironcore Linear Motor

Construction & Features

Iron core linear motors are suitable for use in point to point, high accélération, velocity and load linear motion applications.

■ cpc For motor parometers. force constant refers to ths amount of force produced per one ampere of curent, while motor constant refers to the force produced per Watt and ts representath/e of the motor's efficiency.

As such, the motor constant is a better metric at evaluatirvg motor performance, cpc's linear motors have been designed with the aid of advanced simulation software. As a resuit, for this metric. cpc motors have a higher motor constant.

■ low Cogglng Force

Cogging force originales from the drastic altérations in magnetism on the iron core during transitions across the différent magnetic pôles on the stator.

In this way. by skewing the magnets. the magnetic changes can be lowered. By using advanced software anciysis to do so. cpc has arrived at a design with an exceptionady low cogging force.

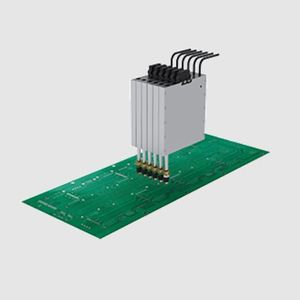

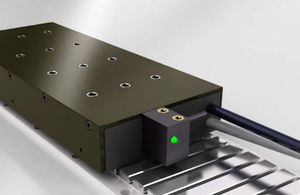

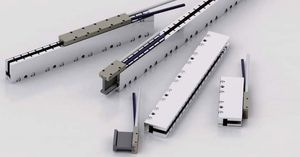

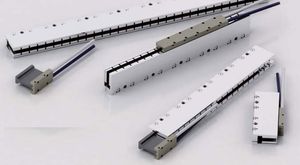

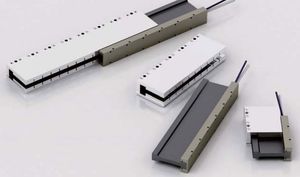

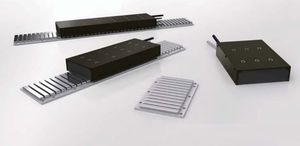

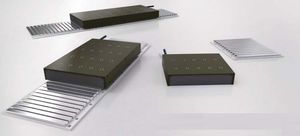

■ - cpc linear motors are composed of two parts: The sfatcr and the forcer.

■ - The forcer is mode by combining coil windings with an ron core which is encopsulated by epoxy inside an outer aluminum shell.

■ - The stator is composed of arrays of permanent mognets on a ferromagnetic backing plate. The magrvets are arranged in an N-S pôle pattern. forming a closed mognetic field loop with the forcer iron core.

VIDEO

Catalogs

No catalogs are available for this product.

See all of CPC‘s catalogsRelated Searches

- Servo-amplifier

- Linear servomotor

- DC servo drive

- Digital servo drive

- DC linear servomotor

- Ironless linear motor

- 24 V servo drive

- RS-232 servo drive

- Iron-core linear servomotor

- AC linear servomotor

- High-performance linear servomotor

- 230 V linear servomotor

- Direct-drive linear servomotor

- Flat linear motor

- 24 V linear motor

- 48 V linear motor

- Aluminum frame linear motor

- 600V linear motor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.