- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

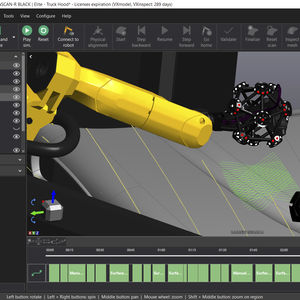

NDT software VXintegritydata analysisreporting

Add to favorites

Compare this product

Characteristics

- Function

- data analysis, reporting

- Applications

- for NDT

Description

Composed of four software modules designed specifically for the NDT industries, VXintegrity combines NDT knowledge and market intelligence to raise the quality of analysis and reporting to a higher level.

NDT PIPELINE INSPECTION

• Data analysis and report generation directly onsite,allowing for rapid decision-making

• Peace of mind through accurate, repeatable, and traceable results

• Reduced latency, as pipes are reburied more quickly

• Ability to conserve data over time, making it possible to compare damage evolution

• Prevention of environmental catastrophe

NDT SURFACE INSPECTION

• Operator-independent measurements

• Algorithm sensitive to the finest detail

• Interaction rule optimized for aerospace, facilitating communication on the extent of damage

• Defect characterization on different aircraft components, sizes, and surface finishes

• Guided workflow approach that simplifies the measurement extraction of 3D scan data and obtains the exact dimensions required for the assessment

NDT PLANT INSPECTION

• Highest accuracy on digital reconstruction

• Technician-independent measurements free from human error at the acquisition stage

• Versatile measurement method for all geometry types, such as spheres, cylindrical heads, tank floors, etc.

• Polyvalent surface damage assessment approach for all types of mechanical damages, such as corrosion, dent, and gouge

• Ability to export inspection results into CSV or STL files for further evaluation

PREVENTIVE MAINTENANCE

• Calculation of wear, corrosion, and erosion rates, as well as deformation, alignment, and ovality

• Advanced and automatic report generation

VIDEO

Catalogs

Related Searches

- Management software solution

- Analysis software solution

- 3D software solution

- Visualization software solution

- Reporting software solution

- Inspection software

- Data analysis software solution

- Control software

- Software module

- Assessment software

- Pipe software

- NDT software

- Management software module

- Surface inspection software

- Quality software module

- Automated software module

- Programming software module

- Quality control software module

- 3D software module

- Pipeline management software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.