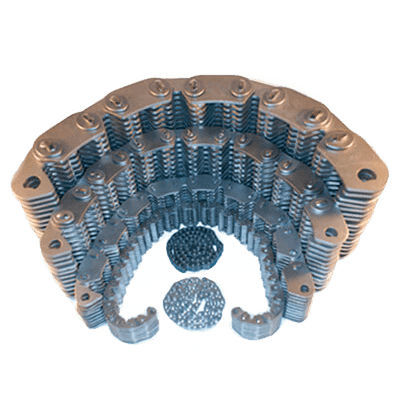

The new series 'SC' chains suffer minimal wear elongation during operation, making them well suited to 'fixed centre' drive applications. The chains can also be used to replace other manufacturers chains on existing applications to increase power ratings. The 'SC' chains are available in standard Centre Guide construction, as shown in the following table; or with either Single or Double Outside Guides. Other widths and guiding arrangements from the standards shown can be supplied as replacements on existing drives on short lead time.

All Cross+Morse chains use the Pin and Rocker design developed in the 'HC' series chains, so eliminating friction and chordal action during articulation allowing the chains to be operated at speeds up to 35 metres/sec, with negligible wear or heat generation. Improved Link design combined with the 'HC' type pins has enabled higher loads to be transmitted, with the chains having twice the power capacity specified in the Standard. The improved Link design reduces stress concentrations giving improved fatigue life and increased tensile strength. Innovative stamping methods in link production maximise the bearing surface area of each link, reducing stress in the chain joint, and chain elongation when operating. All chain links are shot peened to improve fatigue resistance and provide a uniform finish.