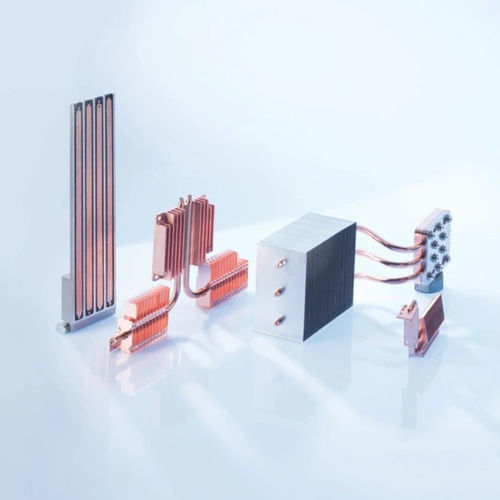

Cooling systems consisting of a heat sink and heat pipes feature excellent heat dissipation even over large distances. The copper heat pipes transfer the heat from the electronic component to a heat sink, which then dissipates the heat into the ambient air. In the case of very high heat generation the heat pipe system can also be combined with a fan for forced cooling.

A heat pipe – generally a copper pipe with an internal capillary structure of sintered copper wire mesh – is a closed system with a coolant in a vacuum, which uses the phase change between evaporation and condensation of the liquid for heat transfer. The coolant (methanol or water) evaporates in the hot zone of the heat pipe, releasing evaporation heat and lowering the pressure in the pipe. As a result of the pressure differential the vapor flows to the cold zone of the heat pipe at the transition to the heat sink and condenses there, giving off condensation heat. Due to the capillary effect generated by the capillary structure in the heat pipe or by gravity, the liquid flows back into the hot zone. The circuit starts anew. In this way, heat pipes dissipate high amounts of heat despite minimal temperature differences. That makes them the most efficient heat exchangers

The advantages of heat pipe systems

Heat pipes can be combined with many different types of heat sinks to meet individual requirements. The cooling capacity of the systems can be improved many times over by increasing the number of heat pipes and/or by combining the system with a fan.Since heat pipe cooling systems operate independently and need no external water pumps or pipes, they also require less maintenance than liquid cooled system