- Electricity - Electronics

- Electronic Component

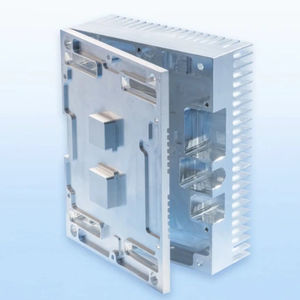

- Aluminum heat sink

- CTX Thermal Solutions

Aluminum heat sink extrudedfor electronicscustom

Add to favorites

Compare this product

Characteristics

- Material

- aluminum

- Options

- extruded, custom, for electronics

Description

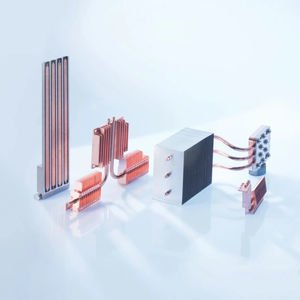

Aluminum profile heat sinks – also known as die-cast or extruded heat sinks, depending on the manufacturing process – are the classic method for cooling of power electronics. Their fins provide a large cooling surface for effective heat dissipation by means of natural convection. Profile heat sinks therefore ensure the stable operation of electronic components and a long service life.

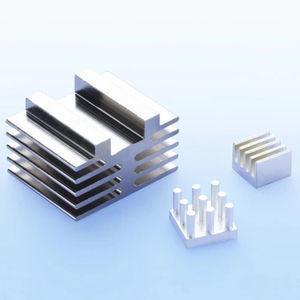

Applications range from cooling of semiconductors in small mobile end devices to cooling of high-power IGBTs in railway technology. There are different methods for mounting them on the electronic component to be cooled: Small profile heat sinks are mounted using clips or soldering pins. Large die-cast heat sinks generally have integrated threads for screwing them in.

Very large selection of die-cast heat sinks

Our portfolio of typical standard profiles – including fin, comb and finger heat sinks, as well as mini heat sinks – is exceptionally large. Our experts will be glad to help you in choosing the right profile heat sink!

And if there is no standard heat sink for your requirements, we – as a specialist for project- and application-specific cooling solutions – will jointly develop the optimal profile heat sink for your application.

Benefit from more than 25 years of experience in the development and marketing of heat sinks.

Our profile heat sinks in figures:

Rth values: 81.6 - 0.04 °C/W

Thermal conductivity: 180 W/mK

Width: 12 - 200 mm – also available up to 1000 mm due to special manufacturing process

Height: 7 - 135 mm is no problem

Bottom thickness: 2.5 mm or higher

Weight: 0.13 - 75 kg/m

The die-casting process inherently involves unavoidable tolerance deviations

Catalogs

No catalogs are available for this product.

See all of CTX Thermal Solutions‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.