- Production Machines

- Other Manufacturing Equipment

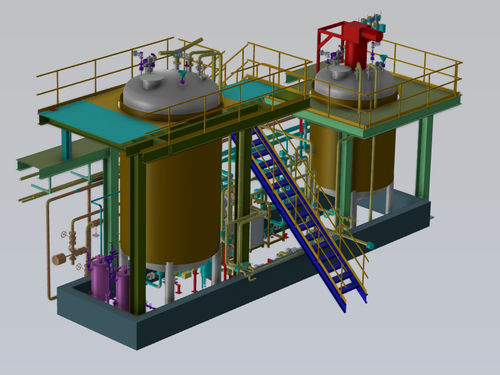

- Batch reactor

- Cukurova Muhendislik Elektrik Elektronik Mak. San.ve tic. A.S.

Batch reactor processcustomcooled

Add to favorites

Compare this product

Characteristics

- Type

- batch

- Applications

- process

- Configuration

- custom

- Temperature

- cooled, with accurate temperature control

- Treatment method

- chemical

- Other characteristics

- exothermic

Description

Prepolymer Reactor Unit is used to produce TDI (toluene diisocyanate) and MDI (diphenylmethane - diisocyanate) based prepolymer, used in thermoplastic or rigid structured thermoset plastics, with high precision.

All prepolymer units are specially designed and manufactured in accordance with customers' needs and demand.

Advantages of Use:

• High precision exothermic reaction control

• Recipe based production, recording, remote control and reporting

• Safe design that has passed Process Hazard Assessment (PHA) Risk Analysis

• Heated lines for protection against isocyanate freezing

• Easy-to-install

• Easy-to-use

Capacity - 5m³ – 25m³

Batch Time - 8 - 10 hours

Heating Fluid - 120 °C Superheated Water

Cooling Fluid - via Cooling Tower Water

Line Heating - Heat Tracing

Control System - PLC, HMI and/or SCADA

Fiiling Speed Control - via Variable Frequency Drive (VFD) on Motors

Blender Speed Control - via Variable Frequency Drive (VFD) on Motors

Catalogs

No catalogs are available for this product.

See all of Cukurova Muhendislik Elektrik Elektronik Mak. San.ve tic. A.S.‘s catalogsOther Cukurova Muhendislik Elektrik Elektronik Mak. San.ve tic. A.S. products

Chemical

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.