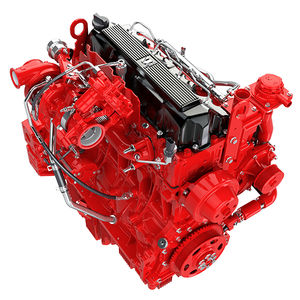

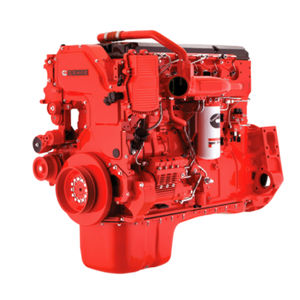

Diesel engine QSF3.8 series4-cylinderturbochargedin-line

Add to favorites

Compare this product

Characteristics

- Type

- diesel

- Number of cylinders

- 4-cylinder

- Technology

- turbocharged, in-line

- Product applications

- agriculture, for mining applications, for construction equipment, rail

- Other characteristics

- compact, air-cooled, with particulate filter

- Power

Max.: 97 kW

(131.883 hp)Min.: 55 kW

(74.779 hp)- Torque

Max.: 488 Nm

(359.9303 ft.lb)Min.: 376 Nm

(277.3234 ft.lb)- Rotational speed

1,500 rpm, 1,600 rpm, 2,200 rpm, 2,500 rpm

(9,424.78 rad.min-1, 10,053.1 rad.min-1, 13,823.01 rad.min-1, 15,707.96 rad.min-1)

Description

Compact Power Redefined.

Achieving near-zero emissions levels in an engine delivering 74 hp to 130 hp (55-98 kW) without compromising power, performance or fuel economy is a big challenge. Yet that’s exactly what Cummins engineers have achieved in the QSF3.8 – without the need to add a DPF to the aftertreatment system. At 74hp, the QSF3.8 uses a simple “fit and forget” Diesel Oxidation Catalyst (DOC). Cummins DOC, a flow-through device requiring no ash-cleaning service, no sensors and no operational lamps in the equipment cab, enables a smaller, easier and more flexible equipment installation than Diesel Particulate Filters (DPF) typically used by many other engines below 75 hp looking to meet the requirement for near-zero emissions.

From 100-130 hp, the QSF3.8 is paired with a Diesel Oxidation Catalyst and Selective Catalytic Reduction (DOC-SCR) system designed by Cummins Emission Solutions (CES). Cummins SCR enables oxides of nitrogen (NOx) conversion to take place at lower exhaust temperatures. CES has manufactured over 1 million SCR systems – and has more experience with this technology than any other company. The Cummins SCR system features a decomposition tube designed to enable more effective mixing of the Diesel Exhaust Fluid (DEF) ahead of the catalyst. Additionally, for certain applications, the QSF3.8 can be paired with an SCR-only aftertreatment system.

Catalogs

No catalogs are available for this product.

See all of Cummins Inc.‘s catalogsRelated Searches

- Diesel engine

- Multi-cylinder engine

- Turbocharged engine

- Cylinder engine

- 4-stroke engine

- In-line engine

- Compact engine

- 6-cylinder engine

- Common rail engine

- Direct injection engine

- Marine engine

- 4-cylinder engine

- Air cooling engine

- Low-noise engine

- Tier 2 engine

- Stage III engine

- Engine for the construction industry

- Gas engine

- Stage V engine

- Air-cooled engine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.