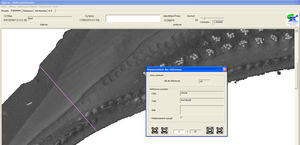

Automatic fault recognition software CYXPERTX-ray image

Add to favorites

Compare this product

Characteristics

- Function

- automatic fault recognition

- Applications

- X-ray image

Description

CyXplus, as expert ...

With over 25 years of experience and around 80 inspection systems installed in tire manufacturing plants worldwide, CyXplus has designed CyXpert software for image analysis and automatic defect detection.

Why ADR (Automatic Defect Recognition )?

ADR software gives the customer a better optimization of its X-ray inspection machine. By analyzing tire X-RAY images as a background task, CyXpert does not affect the machine cycle time. The average cycle time measured by our customers for PCR machines equipped with CyXpert is less than 22 seconds in Automatic mode. Who can do more can do less… CyXpert can also work in semi-automatic mode and let the operator validate the choice of the system.

What kind of defects are detected and recognized by CyXpert?

Thanks to a 0.4 mm accuracy, defects on the tread section, sidewall and bead areas cannot escape the vigilance of CyXpert. The impressive list of detectable defects, as a result of CyXplus engineering listening to customer needs, is regularly updated with new features. The main requests for detection are distances between consecutive belts, between cords, between the ply turn up chafers edges, but also cord angle, cord integrity failure, number of cords, belt extraction, foreign materials, air traps, etc.

Catalogs

No catalogs are available for this product.

See all of CyXplus‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.