- Metrology - Laboratory

- Metrology and Test Equipment

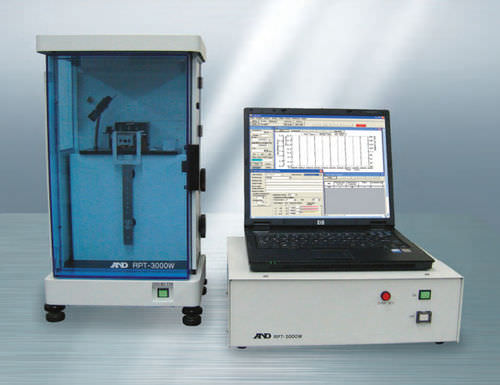

- Viscoelasticity testing machine

- A&D COMPANY, LIMITED

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Viscoelasticity testing machine -100 °C ... +400 °C | RPT-3000Wmaterialmechanicalvertical

Add to favorites

Compare this product

Characteristics

- Test type

- viscoelasticity

- Test material

- material

- Technology

- mechanical

- Configuration

- vertical

Description

This instrument allows measurement of visco-elastic physical properties under a curing process and the surface layer physical properties of the material being measured and other materials such as inorganic materials like concrete, cosmetics, paper and foods. This means that the test method does not depend on the substrate. Therefore, this instrument has applications for the development/improvement, quality evaluation, designing, trouble-shooting, and the production line and life evaluation of materials.

All materials transform from a liquid state to a solid state through certain actions (heat, light, time and others) and produce various physical properties. The change in phase from a liquid to a solid causes various problems. The most important item to evaluate from among the various material evaluations is the change in age of the chemical-physical performances in the process of curing and drying from a liquid state to a solid state.

Measurement

Fix the test piece coating plate on the cooling/heating block. Set the pendulum so that the knife-edge, the fulcrum of the swing, comes vertically into contact on the test piece coated surface. Apply free vibration to the pendulum. For measurement of physical properties, use a cylindrical edge. By analyzing this vibration, the curing process and surface's physical properties can be evaluated.

Features

-Coating Thickness Resolution: 0.01 ìm - 7mm

-Period of Vibration:0.05 to 2.000sec

-Logarithmic Damping Ratio: 0.001 to 6.000sec

-Test Temperature: -100 to +400 degree Celsius

-Measurement Time: 1 to 9999 minutes

Catalogs

No catalogs are available for this product.

See all of A&D COMPANY, LIMITED‘s catalogsRelated Searches

- Test machine

- Measuring device

- Material testing machine

- Portable testing system

- Compression test machine

- Vertical test machine

- Universal test machine

- Digital measuring device

- Tensile test machine

- Flexure testing machine

- Precision test machine

- Inspection machine

- Mechanical test machine

- Viscosity measurement device

- Force test machine

- Tabletop testing machine

- Laboratory viscometer

- Friction test machine

- Force measuring device

- Field measuring instrument

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.