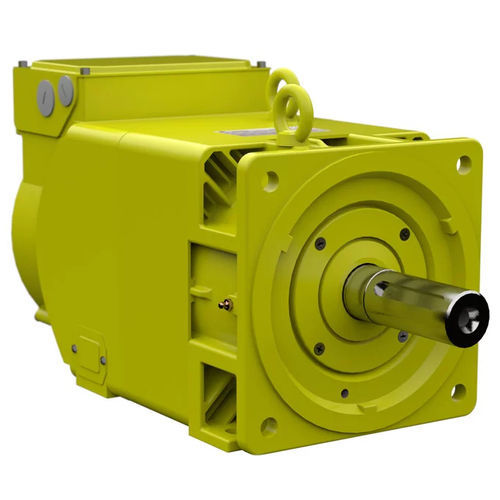

3-phase motor DAM seriesasynchronous400 Vsmall

Add to favorites

Compare this product

Characteristics

- AC/DC

- 3-phase

- Type

- asynchronous

- Voltage

- 400 V

- Configuration

- small

- Number of poles

- 2-pole

- Applications

- spindle

- Other characteristics

- high-performance

- Power

Min.: 2 kW

(2.719 hp)Max.: 100 kW

(135.962 hp)- Rotational speed

1,000 rpm, 1,500 rpm, 2,000 rpm

(6,283.19 rad.min-1, 9,424.78 rad.min-1, 12,566.37 rad.min-1)

Description

D.Electron, in collaboration with the leading Italian motor manufacturers, is able to supply CNC complete packages, accessory drives and motors including spindle motors. These are special asynchronous motors of particularly small size and similar to the corresponding d.c. motors for high performance and variable speed applications with flux control vector inverter power supply.

The particularly accurate mechanics and the innovative electromagnetic project allow for rotation regimes with constant power, up to 9000 rpm. The efficient cooling of the case with an auxiliary electric fan ensures the small dimensions and the high continuous torques even at low revs.

Thermal probe

The motors are equipped with a pair of PT1000 thermal sensors inserted in the stator winding and connected via the encoder connector. The D. Electron Z-Star2 drive system can monitor the motor temperature during operation.

Balancing

All motors are full key balanced (EN 60034-14 / VDE 0530 part 14 type A), a half key balancing is possible on request.

Cooling

The motors are servo-ventilated, on request the cooling flow can be suctioning with respect to the motor shaft side.

Connections

The standard provision always includes the terminal box for power, while a connector is provided for the encoder and the fan. As standard, the terminal box is provided above the motor with connections facing left when viewed from the motor shaft side. On request, D.Electron supplies the wired cables for a mobile laying in compliance with the most severe operating conditions.

Catalogs

No catalogs are available for this product.

See all of D.Electron‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.