- Industrial machines and equipment

- Surface Treatment Equipment

- Spray cleaning machine

- D.W. Renzmann Apparatebau

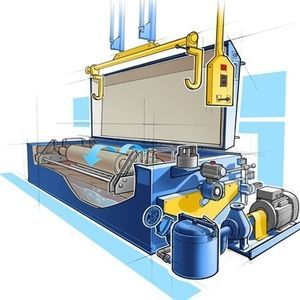

Water cleaning machine CLEANfleXsprayautomaticprocess

Add to favorites

Compare this product

Characteristics

- Technology

- water, spray

- Operational mode

- automatic

- Applications

- process

- Other characteristics

- ATEX, stainless steel, compact, with rinsing

Description

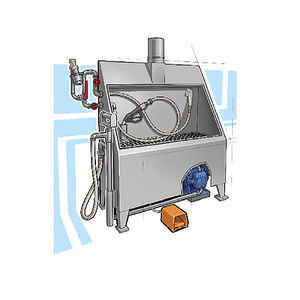

With the washing machines type CLEANfleX, we present its successor model of the washing machine type 100 from the series of systems to be loaded from above.

In times of declining run-time and more frequent job changes, the efficient cleaning of ink-carrying printing unit components is becoming increasingly important.

The CLEANfleX washing machines clean ink trays, doctor blades, buckets and other printing press parts are available in the following variants:

CLEANfleX-ex : for solvents with flash point 55°C

CLEANFleX-aqua: mild - and highly alkaline cleaner

Responsible for the good cleaning result:

A short spray distance in combination with a high spray pressure ensures the good cleaning result.

The process is supported by oscillating rotational movements of the spray bars

The process is supported by oscillating rotational movements of the spray pipes.

The CLEANfleX is loaded at a comfortable height from above. Like its predecessor, the model is robust, easy to maintain and meets all safety requirements for solvent washing machines.

The usable height of the system is 400 mm, the width 600 mm. Three length variants are available: 1000, 1500 and 2000 mm

In contrast to the previous model, the CLEANfleX has a specially shaped lid, which allows convenient loading and is equipped with a pneumatic clamping device.

The measurement of the filling volume in the detergent container, sealed off to the washing chamber, is carried out by a hydrostatic measurement. Several filling levels are recorded and displayed on

Catalogs

Other D.W. Renzmann Apparatebau products

Washing machines Graphic Industry

Related Searches

- Automatic washing machine

- Water washing machine

- Stainless steel washing machine

- Process washing machine

- Spray washing machine

- Parts washing machine

- Solvent washing machine

- Manual washing machine

- Compact washing machine

- Automotive washing machine

- Washing machine with rinsing

- Robust washing machine

- High-pressure washing machine

- Optical cleaning system

- Brush washing machine

- Washing machine with basket

- Compressed air washing machine

- ATEX washing machine

- Rotary washing machine

- Vertical washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.