- Industrial machines and equipment

- Surface Treatment Equipment

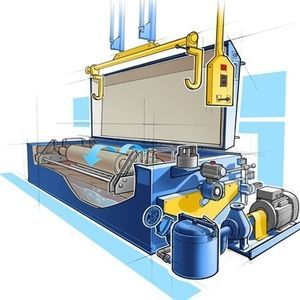

- Solvent cleaning machine

- D.W. Renzmann Apparatebau

Explosion-proof cleaning machine 300solventsprayautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- solvent, spray

- Operational mode

- automatic

- Applications

- for the printing industry, for the recycling industry

- Other characteristics

- explosion-proof, ATEX, with rinsing

Description

Explosion proof device, according to ATEX, for washing printing press parts with all common solvents

Accessible at floor level with washing carriages, with closed washing chamber

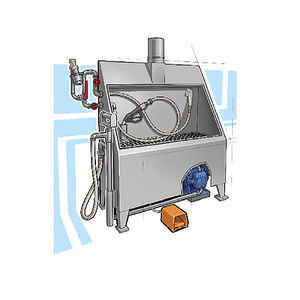

Operating of machine is only possible with closed lift lid

Washing spray system with oscillating rotating spraying pipes

Fixed spray rinsing system

Heavy-duty washing/pump ex-motor unit

Output of recirculation pump according to washing pump guarantees an even recycling of the injected solvent

Drain container with filling level control as run-down container for emptying pump

Supply of solvent from separate decanting container

Removable filters for the protection of the spray system, the washing pump and the pipes

Flap for inspection and maintenance

Inner exhaust with heavy-duty ventilator and pneumatically controlled air intake and air mix valves

Automatic washing program (SPS); including washing – dripping – rinsing dripping – exhaust; all program steps can be selected individually

Accessories

Parts washing carriage, made of stainless steel

Support for gravure cylinders

Washing carriage for gravure cylinders including rotation device

Washing carriage for containers

Transportation device for gravure trolleys

Tube rinsing device

Self cleaning device

Solvent cooling (thermostatic valve, water cooling or heat exchanger)

Exhaust

Solvent content concentration control and regulator system for connection to an exhaust air puryfier

Other D.W. Renzmann Apparatebau products

Washing machines Graphic Industry

Related Searches

- Automatic washing machine

- Water washing machine

- Stainless steel washing machine

- Process washing machine

- Spray washing machine

- Parts washing machine

- Solvent washing machine

- Manual washing machine

- Compact washing machine

- Automotive washing machine

- Washing machine with rinsing

- Robust washing machine

- High-pressure washing machine

- Optical cleaning system

- Brush washing machine

- Washing machine with basket

- Compressed air washing machine

- ATEX washing machine

- Rotary washing machine

- Vertical washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.