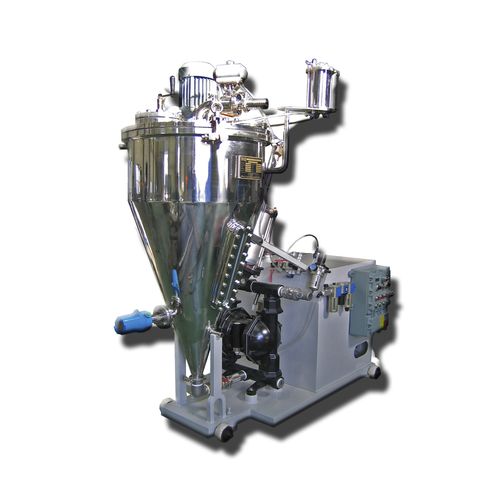

Continuous High Performance Deaeration

During continuous deaerating process of liquid to high viscosity products, a dynamic process Mechstar® Vacuum Deaerator offers a highly efficient, cost-effective solution. This can be tailored to individual requirements, contributing both to quality assurance and process optimization. Deaerated products having a smooth, glossy, foam-free surface are chemically more stable and have a longer shelf life. And the benefits reach far beyond product quality: deaerated products are more dense making precision dosage that much easier and allowing pack volumes to be reduced.

•Paints and varnishes

•Cosmetic

•Agro and household chemicals

•Adhesives

•Food

•Coatings

•Deaerated products having a smooth, glossy, foam-free surface, are chemically more stable and have a longer shelf life.

•Increasing specific weight, reduces packing volume and allows smooth operation of filling equipment providing uniform filling volume.

•Preventing reactions such as oxidation and tendency of grease and oil to run rancid.

•A completely packaged plant consists of its own electrical control panel, discharge pump and vacuum pump.

•Enhances product-quality in long-time stability.

•In portable system you can use wherever you want to carry.

•Useable even on delicate emulsions by imparting minimal temperature and shear action to your product.

•A dynamic process Vacuum Deaerator offers a highly efficient, cost-effective solution