- Industrial machines and equipment

- Mixing and Dosing

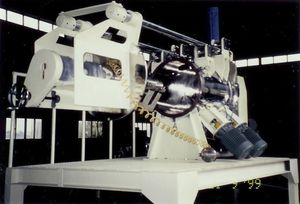

- Planetary mixer

- DAESUNG CHEMICAL MACHINERY IND.CO.

- Products

- Catalogs

- News & Trends

- Exhibitions

Planetary mixer DSPM seriesbatchsolidvacuum

Add to favorites

Compare this product

Characteristics

- Technology

- planetary

- Batch/continuous

- batch

- Product type

- solid

- Other characteristics

- vacuum, steel

- Applications

- for the food industry, for the chemical industry, for the pharmaceutical industry

- Engine power

Min.: 5.6 kW

(7.61 hp)Max.: 45 kW

(61.18 hp)- Capacity

Min.: 100 l

(26.42 gal)Max.: 1,500 l

(396.26 gal)- Empty weight

Min.: 2,300 kg

(5,070.6 lb)Max.: 11,500 kg

(25,353.2 lb)

Description

Special Mixing, Kneading System with High Portion Pigment and Liquid in High Viscosity

Mechstar® Planetary Mixer is an invaluable multi-purpose mixer for mixing and kneading of solid pigment and liquid materials in high viscosity. The rotation of two blades and one orbital motion can make the mixture a highly kneading effect with close interval of rotations and detailed clearance between blades and tank. Also, Planetary Mixer is possible mixing the various lines from low to high viscosity.

•High Viscosity Paint

•Electronic Material

•Pigment

•Adhesives

•Food

•Agro-Chemical

•Pharmaceuticals

•Pape

•Structure Form are two types such as one-cylinder type and two-cylinder for head lifting.

•Vacuum System is possible to process defoaming

•Made of welded steel plate, the frame is closed and all standard and driving elements are housed inside of it.

•Solid with the machine structure, the top head is equipped with a closing hood fitted with a feeding hopper, sight glass and lamp for watching the process. The hood is reinforced and provided with a vacuum gauge and seals for vacuum mixing.

•Additional one or two agitator can be adopted to high viscosity, fine dispersion.

•Agitation Mix is possible from low to high viscosity.h viscosity.

Other DAESUNG CHEMICAL MACHINERY IND.CO. products

Mixer

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Stainless steel agitator

- Agitator for the chemical industry

- Horizontal grinding mill

- In-line mixer

- Food lump breaker

- Horizontal blender

- Agitator for the pharmaceutical industry

- Rotor lump breaker

- Paddle blender

- Impact grinding mill

- Homogenizer for the cosmetics industry

- Vacuum homogenizer

- Plastic pulverizer

- Mill for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.