- Industrial machines and equipment

- Mixing and Dosing

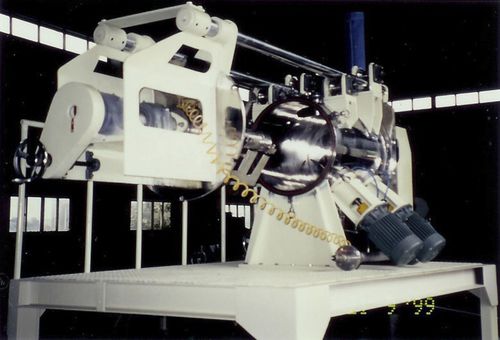

- Paddle mixer

- DAESUNG CHEMICAL MACHINERY IND.CO.

- Products

- Catalogs

- News & Trends

- Exhibitions

Paddle mixer continuousfor liquidscutting

Add to favorites

Compare this product

Characteristics

- Technology

- paddle

- Batch/continuous

- continuous

- Product type

- for liquids

- Other characteristics

- cutting

- Applications

- for the food industry, for the pharmaceutical industry, for the plastics industry, for the paper industry

- Capacity

Max.: 50,000 l

(13,208.6 gal)Min.: 50 l

(13.21 gal)

Description

Mechstar® Turbulent Mixer is extended by additional, laterally installed homogenizers equipped with cutting elements of different types. Thus the system is suitable for a large variety of process technical tasks. This Turbulent Mixer is based on the turbulent-System is easy to clean and requires only very little maintenance and machine sizes are available ranging from 50 liter up to 50000 liter in compliance with another.

•Pigments / Dyes

•Pharmaceuticals

•Paper Industry

•Wastes Treatment

•Food

•Plastic

Practicable Process

•Practicable Process

•Moistening ProcessDrying Process

•Kneading Process

•Melting Process

•Granulation Process

•The special-design mixing paddle give the effect of the biggest mixing surface and the efficiency of short mixing time.

•The intensive axial and radial mixing pattern give an effective shearing to the product.

•The special design of mixing paddles with close scrapers is able to creative the perfect mixing zone without dead space.

•Additional homogenizing device installed in side-wall provide the fully developed micro phase.

•The structural mixing paddle force effectively to move the final product through the discharge to the next process.

Other DAESUNG CHEMICAL MACHINERY IND.CO. products

Mixer

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Stainless steel agitator

- Agitator for the chemical industry

- Horizontal grinding mill

- In-line mixer

- Food lump breaker

- Horizontal blender

- Agitator for the pharmaceutical industry

- Rotor lump breaker

- Paddle blender

- Impact grinding mill

- Homogenizer for the cosmetics industry

- Vacuum homogenizer

- Plastic pulverizer

- Mill for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.