Pick-to-light order-picking system Assort

Add to favorites

Compare this product

Characteristics

- Type

- pick-to-light

Description

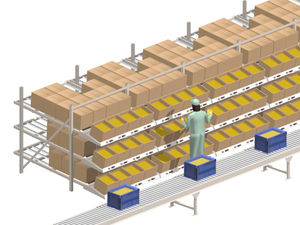

Daifuku Webb's put-to-light system queues workers of where to put items on a rack or shelf. Designed as a space-efficient, economical method for consolidating orders for small parts, it supports high-speed manual sortation with near 100% accuracy. Our put-to-light system can integrate with AS/RS, conveyor, overhead monorail and STV.

How it works

Input:

Control software assigns customer's order to a specific location.

Worker scans item's barcode. A flashing light identifies the location to place the item.

Worker places the item in the location and presses the light to confirm the placement of the item to the control software.

Output:

When the order is complete a different colored light indicates that the order is complete.

Box is pulled from the rack and sent to shipping for packaging and final paper work.

Catalogs

No catalogs are available for this product.

See all of Daifuku webb‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.