- Products

- Catalogs

- News & Trends

- Exhibitions

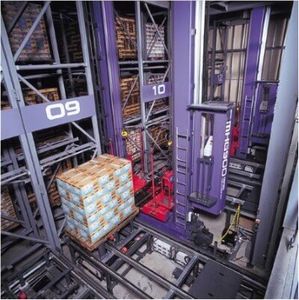

Shuttle storage system Shuttle Rack M

Add to favorites

Compare this product

Description

Daifuku's multi shuttle system "Shuttle Rack M" is a fast, vehicle-type AS/RS designed to provide temporary storage, sorting and sequencing function. It is perfect for following needs.

Buffering between the primary picking by batch and the secondary assorting by orders.

Picking inventory for Goods-To-Person picking system.

Buffering products from manufacturing lines and feeding to palletizing robots by product group.

Buffering of orders ready for shipping and quick feeding in group or sequence to delivery trucks.

Features

Easy Maintenance

Faulty shuttles can be replaced with little disruption to the system. Other shuttles continue to operate while maintenance is being performed on one shuttle. By controlling the number of active shuttles, maintenance can be systematically performed on each shuttle without interrupting the handling process.

Energy Saving

The system has one shuttle vehicle installed on every level. Each shuttle travels at high speeds to quickly store and retrieve loads. By using lightweight vehicles to transport loads, the "Shuttle Rack M" consumes 60% less power per cycle than conventional crane systems.

Related Searches

- Rack system

- Storage warehouse rack

- Pallet racking

- Box rack system

- Vertical automatic warehouse

- Mobile rack

- Shelf

- Order-picking system

- Storage shelf

- Shuttle storage system

- Automated racking

- Modular automatic warehouse

- Pallet automatic warehouse

- Pick-to-light order-picking system

- Compact automatic storage system

- High-density automatic storage system

- Digital order-picking system

- High-speed automatic storage system

- Cassette automatic storage system

- Small load automatic storage system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.