- Machine-tools

- Machining Center

- Titanium machining

- Dainichi Manufacturing Co., Ltd.

Aluminum machining stainless steeltitaniumiron

Add to favorites

Compare this product

Characteristics

- Treated material

- aluminum, stainless steel, titanium, iron, Inconel, Hastelloy®

- Applications

- for pump, turbine, for aeronautics, for robotics

- Product applications

- screw

- Other characteristics

- CNC, 5-axis

Description

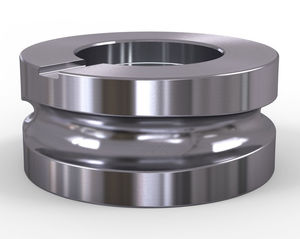

Simultaneous 5-axis processing for 304-dimensional machining of components like impellers.

Precision machining of products specified with strict geometric tolerances.

Materials include heat-resistant Ni-based alloys (Inconel, Hastelloy, etc.), heat-resistant cobalt-based alloys, stainless steel (316, 310L, 630S, 420, 2J440, 431C, 3, etc.), AL, Ti, SC, FC, and others.

To ensure quality, we have established an inspection system using a 3D coordinate measuring machine in a temperature-controlled environment. Additionally, measurement of 3D shapes through scanning is possible. We inspect the shape of 3D products, castings, and fabricated materials using a 3D laser scanner, comparing the 2D model with scanned data to confirm the shape.

Processing and assembly of measuring instrument components - Automatic load cells.

A consistent production system from processing and supplying over 630 parts to the final product assembly.

Load cell processing with SUS304 attachments.

Materials include SUS5052, A3, etc.

Machining and assembly of compressor-related parts - Valves.

From machining the intake valve adjustment components for compressors to assembly, delivered to Kobe Steel, Ltd.

Load cell processing with SUS5052 attachments.

Materials include A4, AC4C etc.

Machining and assembly of pump-related parts - Gear pumps, etc.

Machining and assembly of pumps (gear pumps, centrifugal pumps, piston pumps, etc.) for major shipbuilding companies.

Load cell processing with SUS3 attachments.

Materials include FC, FCD, BC etc

Other Dainichi Manufacturing Co., Ltd. products

Processed Goods

Related Searches

- Machining service

- Milling machining

- Metal milling machining

- CNC milling machining

- ISO machining

- ISO 9001 milling machining

- Turning machining

- Automotive milling machining

- Metal turning machining

- Industrial milling machining

- CNC turning machining

- Small series milling machining

- Medium series milling machining

- Precision turning machining

- ISO 9001 turning machining

- Prototyping milling machining

- 5-axis milling machining

- Stainless steel milling machining

- Individual milling machining

- Aluminum milling machining

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.