1-axis machining center BASP serieshorizontaldrillingprecision

Add to favorites

Compare this product

Characteristics

- Number of axes

- 1-axis

- Spindle orientation

- horizontal

- Associated functions

- drilling

- Other characteristics

- precision, automated loading/unloading, with electronic control

Description

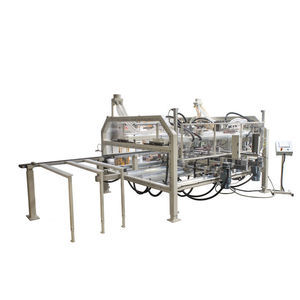

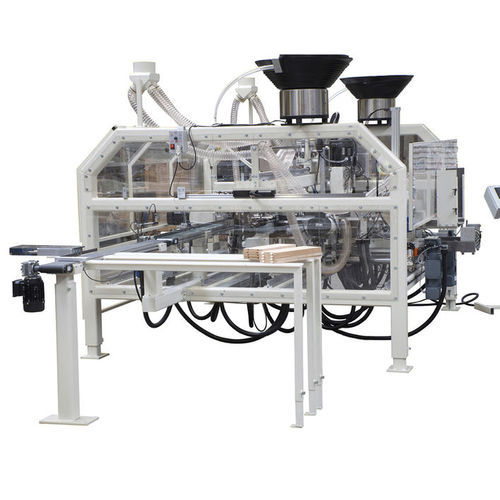

Not two machines are alike from the Dan-List Classic BASP series.

The Dan-List Classic BASP series is based on the same principles as the Dan-List Classic BA series: Quality, reliability, precision, efficiency – built for the 24/7 prduction.

Apart from drillings, the Dan-List BASP series can be equipped with additional operations, such as automatic dowel insert, trim saws, various routing operation, grovving units, or connected to machines in a fully automatic production line.

The Dan-List BASP machines are always prepared in a very close cooperation with our customers, listening very carefully to their specific demands, and from there – a proposal for a specific custom made machine will be made.

The operator controls all operations from a custom made touch screen in local language.

Main features are:

• Flexibility

• High capacity.

• Exact drillings.

• Two or more working stations.

• Drill head – revolving 360º around its own axis.

• Drilling unit - revolving 90º around its own axis.

• Digital read out for exact positioning of drilling units.

• User friendly touch screen in local language.

• Strong and solid machine frame.

• Maximum operator safety.

• Built to last.

• CE certified.

Working cycle:

1. Enter program from touch screen.

2. Move drilling units to correct position.

3. Start machine.

4. Work piece is automatically pushed to first working station, clamped

and drilled.

5. Afterwards moved automatically to second working station, where

remaining drillings are made.

6. When finished – the workpiece is automatically returned to the

operator.

VIDEO

Catalogs

Dowel Drilling Machine

2 Pages

Related Searches

- CNC machining center

- Precision CNC machining center

- Drilling machine

- Milling machine

- Horizontal CNC machining center

- Drilling CNC machining center

- Vertical drilling machine

- CE router

- Boring center

- Horizontal boring machine

- Wood router

- Horizontal milling machine

- Electric drilling machine

- Drilling milling machine

- Automatic router

- Compact drilling machine

- Copy router

- Vertical boring center

- Conventional boring machine

- PLC-controlled drilling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.