- Detection - Measurement

- Flow, Pressure and Level Measurements

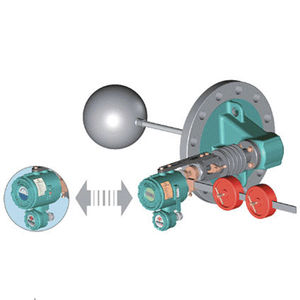

- Magnetic float level transmitter

- Dandong Top Electronics Instrument (Group) Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Magnetic float level transmitter UHC seriesfor liquidsfor storage tanks

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic float

- Medium

- for liquids

- Applications

- for storage tanks

Description

UHC magnetic level gauge provides a safer, more reliable and more visible option than conventional glass level gauge. The float moves up and down with the change of level, and the float transmits the level signal through the coupling magnetic field, which divides into the local indication type and the remote transmission output type.

Chamber and float have a variety of materials and pressure-grade options and are suitable for complex process applications of current major operating devices.

Features

1.The float adopts 304,316 L, TA2 and TC4 material. It has good temperature resistance and can reach to 450℃.

2.The welding process meets the requirements of PED welding process. The chamber is made of 304,316 L. The maximum pressure can reach to 26 MPa.

3.Local indicator type and remote output type with level alarm are optional.

4.According to customer requirements, through a variety of production types, the products can be applied to a variety of working conditions.

Main Technical Parameters

1. UHC Magnetic level gauge side-mounted type local indicator

1.1 Side-mounted type magnetic level gauge (normal type)

Scope of application: The level gauge is the most common used side-mounted magnetic level gauge. It is suitable for level or interface measurement with nominal pressure which is not greater than 6.3MPa and the medium temperature is 0℃~+350℃.

Measurement range: 200mm~6000mm (Out of range is acceptable)

Nominal pressure: ≤6.3MPa

Nominal diameter: DN25 (or on request)

Ambient temperature: -40℃~+80℃

Medium temperature: 0℃≤T<350℃

Accuracy: ±5mm

Density: Level: ρ≥0.36g/cm3 Interface: ρ1-ρ2≥0.1g/cm3

Wetted material: 304, 316L or on request

Catalogs

No catalogs are available for this product.

See all of Dandong Top Electronics Instrument (Group) Co.,Ltd‘s catalogsOther Dandong Top Electronics Instrument (Group) Co.,Ltd products

Level Transmitters

Related Searches

- Flowmeter

- Volume flowmeter

- Liquid flowmeter

- Level limit switch

- Liquid level limit switch

- Gas flowmeter

- Stainless steel flowmeter

- Waterproof flowmeter

- Industrial flowmeter

- Protection level level switch

- In-line flowmeter

- Float level switch

- Precision flowmeter

- Level transmitter

- Mass flowmeter

- Liquid level transmitter

- Digital flowmeter

- Analog level transmitter

- Flange flowmeter

- Explosion-proof flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.