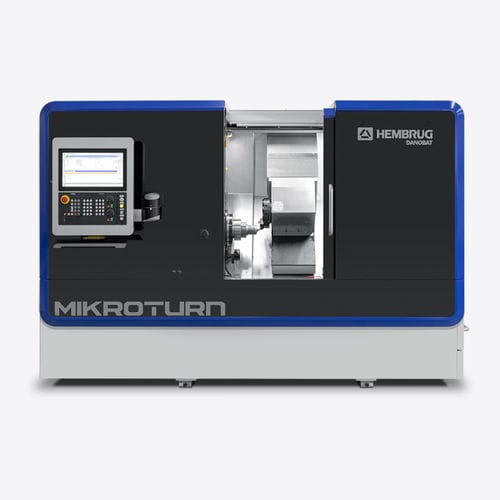

The Mikroturn® is an ultra precise, fully hydrostatic, horizontal hard turning machine for hardened workpieces up to 70 HRC.

Flexibility is the norm

You can machine workpieces with complex contours, or perform combinations of ID and OD machining in a single clamping, avoiding re-clamping errors.

Change your workpiece and set-up in under 30 minutes

• Very simple changeover and set-up. In many cases, it takes under 30 minutes

• High material removal rates, even in hardened steel or carbide

• Ideal for small and medium-sized batches requiring high flexibility

> 40 years of knowledge in hydrostatic bearing systems

• No wear, and thus, consistent accuracy for decades

• Superb damping properties

• High stiffness, regardless of the speed

• Good thermal stability

• Long tool life

Consistent accuracy, even after 30 years

The absence of metal-to-metal contact between moving machine elements leads to:

• A completely wear-free platform

• Low operational costs

• Repeatability even after 30 years

Workpiece and tool holding

• Air chuck

• Magnetic chuck

• Fixed tools

• Live tooling

Increased stiffness and stability for long workpieces

• Tailstock

• Steady rest

Measuring system

• Part probe

• Tool measurement

• Tool wear measurement camera system

• In-process tool life measurement

Additional finishing options

• Grinding spindle

• Stone finishing