- Machine-tools

- Machining Center

- CNC lathe

- DANOBATGROUP

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

CNC lathe DFRhorizontalfor train wheel machining

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- horizontal

- Applications

- for train wheel machining

- Diameter

375 mm, 1,400 mm

(14.76 in, 55.12 in)- Nominal power

30 kW

(40.8 hp)

Description

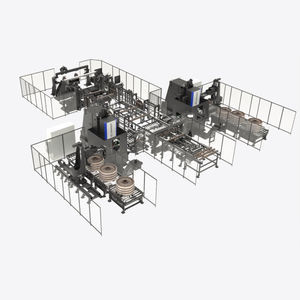

DFR (single and tandem version) is specifically designed and manufactured to reprofile locomotives and freight cars.

Specialised lathe for locomotive and freight car wheel reprofiling

Up to 40 ton axle-load

Centerless or between centers machining

Different profile contours can be generated for wheel life increase

Brake disc facing possibility

Integrated diameter & wear measuring system

Automatic clamping option

Great strength for high cutting forces and hardened materials

Full cast iron structure that absorbs vibrations

Best performance against temperature variations

Linear & prismatic guiding system for high-cutting forces

Extendable toolholder to improve accessibility for brake disc facing

The most cost-effective reprofiling process

Able to reprofile a wide range of wheel profiles with standard tools:

Minimal tooling cost

Less downtime, thanks to quick and easy insert indexing

High flexibility: The same tool can produce multiple toolpaths or wheel profiles

Optional brake disc facing

Smart machines make smart decisions

The DFR adjusts the process parameters according to the incoming condition of each wheelset.

Avoid human error, improve process reliability, reduce cycle time and minimize operating costs.

If you need to minimise downtime, tandem is your solution

The DFR tandem reprofiles two wheelsets simultaneously.

Significantly reduces the time for turning a complete unit

The machine adjusts the wheelbase automatically

You need only one operator

Turning operations

Measuring (1) (6)

Wheel profile (2)

External faces (3)

Wheel mounted brake-disc facing (4)

Axle mounted brake-disc facing (5)

Wheelset clamping

Centerless

Between centers

VIDEO

Catalogs

No catalogs are available for this product.

See all of DANOBATGROUP‘s catalogsOther DANOBATGROUP products

Machines for railway wheelsets, wheels and axles

Related Searches

- Turning center

- CNC turning center

- High-precision turning center

- Vertical turning center

- Compact turning center

- High-speed turning center

- Multi-spindle turning machine

- Boring center

- Large part turning center

- 2-spindle turning center

- Grinding turning center

- CNC boring center

- Hydrostatic turning machine

- Wheel turning center

- Long workpiece turning center

- Finishing turning center

- High-capacity turning center

- Vertical boring center

- Heavy turning lathe

- High-precision boring center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.