- Machine-tools

- Machining Center

- CNC boring machine

- DANOBATGROUP

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

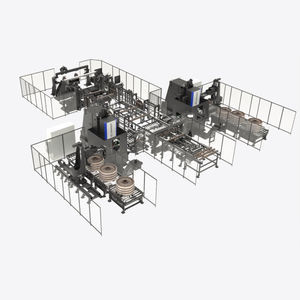

CNC boring machine MVverticalfor railway applicationshigh-precision

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Applications

- for railway applications

- Other characteristics

- high-precision

- Power

22 kW

(29.91167 hp)

Description

Specially designed and manufactured for high-precision railway wheel hub boring.

The machine features the latest smart manufacturing technology to maximise your throughput.

Automatically adapts to the cutting conditions in-process

MV automatically adjusts cutting parameters (depth of cut, feed rate, etc.) based on real-time measurements of the spindle’s power and torque.

Reduces cycle time

Increases process reliability

Extends insert life

Reduce your roughing time by 20%

Due to the machine’s ability to automatically vary the cutting speed in-process, roughing cut times are reduced by 20%.

No need for additional measuring systems

MV doesn’t need additional measuring devices to increase efficiency. It automatically sets the location of the upper and lower faces of the hub, optimising machining length to real hub length.

User-friendly programming

Sequential procedures guide the operator through the steps of the machining process:

Centralised information for fast and simple access

Digital apps: alarms & troubleshooting, a preventive maintenance planner, and more

Roughing

Wide range of cutting insert geometries

Option to mount 2 inserts for optimum machining at greater depths

Finishing

You can mount a wide range of insert geometries to obtain the best surface finish.

Entry/exit chamfer or radius

The machine allows chamfers or radii to be made on both the top and bottom face of the hub.

Oil groove

Need to machine an oil groove? No problem, the versatility of the tool used allows you to do so easily.

VIDEO

Catalogs

No catalogs are available for this product.

See all of DANOBATGROUP‘s catalogsOther DANOBATGROUP products

Machines for railway wheelsets, wheels and axles

Related Searches

- Turning center

- CNC turning center

- High-precision turning center

- Vertical turning center

- Compact turning center

- High-speed turning center

- Multi-spindle turning machine

- Boring center

- Large part turning center

- 2-spindle turning center

- Grinding turning center

- CNC boring center

- Hydrostatic turning machine

- Wheel turning center

- Long workpiece turning center

- Finishing turning center

- High-capacity turning center

- Vertical boring center

- Heavy turning lathe

- High-precision boring center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.