- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

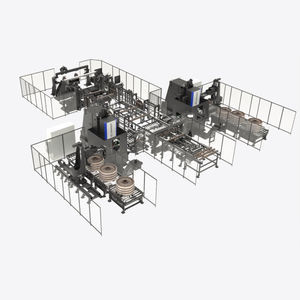

Metal parts production cell UARCautomaticultrasonic

Add to favorites

Compare this product

Characteristics

- Finished product

- metal parts

- Other characteristics

- automatic, ultrasonic

Description

This cell reconditions used railway axles very efficiently, thanks to a key feature: almost all operations are automated.

The cell includes cleaning, measuring and repair units. It also performs post-process ultrasonic and magnetic particle inspections.

Recondition 100 axles per shift

This cell identifies and classifies NON-repairable axles automatically, increasing your efficiency and capacity. Repair up to 100 axles per shift.

Operated by only 2 people

Only 2 people are required for the complete reconditioning of the axles, as the part transfer and most of the equipment is fully automatic.

The measuring station ensures high repeatability and reliability

A dimensional check of the axle is critical in determining its condition and deciding whether it can be safely returned to service.

Outcomes from axle inspection can be centrally stored in a database

This data can be consulted at any time for supporting the decisions you make.

We offer services to keep your UARC in the best condition

Yearly preventive maintenance, calibration, and customised plans managed by a seasoned team

We are prepared to assist you remotely. We respond and manage your request worldwide

VIDEO

Catalogs

No catalogs are available for this product.

See all of DANOBATGROUP‘s catalogsOther DANOBATGROUP products

Machines for railway wheelsets, wheels and axles

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.