- Metrology - Laboratory

- Metrology and Test Equipment

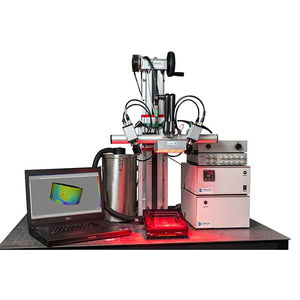

- Shape measuring system

- Dantec Dynamics A/S

Deformation measuring system Q-400 DICshapestrainoptical

Add to favorites

Compare this product

Characteristics

- Measured physical value

- shape, deformation, strain

- Technology

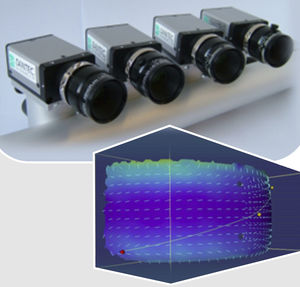

- optical, 3D

- Configuration

- portable

- Other characteristics

- non-contact, high-speed

Description

The Digital 3D Image Correlation System Q-400 is an optical measuring device for true full-field, non-contact and three-dimensional measurement of shape, displacements and strains on components and structures made from almost any material.

The Q-400 system is used for determination of three-dimensional material properties in tensile, torsion, bending or combined tests. In addition, deformation and strain analysis can be applied to fatigue tests, fracture mechanics, FEA validation and much more.

A Wide Range of Applications

Its flexible design opens a wide range of applications from microscopic investigations on microelectronic or biomedical materials up to large scale measurements of aerospace, automotive, marine and railway components.

- Advanced materials (CFRP, wood, fiber injected PE, metal foam, rubber, …)

- Component testing (shape, displacements, strains,…)

- Material testing (Young’s Modulus, Poisson’s Ratio, Elasto-Plastic Behaviour)

- Fracture mechanics FEA validation

- High-Speed applications (dynamic measurements, transient events)

VIDEO

Catalogs

Wind Turbine Optimization

8 Pages

Other Dantec Dynamics A/S products

DIC - Digital Image Correlation

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Temperature measuring device

- Automatic measuring device

- Benchtop measuring device

- Non-contact measuring machine

- Laser measurement system

- Geometry measuring device

- Extensometer

- 3D measuring machine

- Optical measuring device

- Gas measuring instrument

- High-speed measuring machine

- PH measuring device

- Shape measuring machine

- Moisture measuring device

- Non-contact measuring device

- Temperature measurement system

- Laser measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.