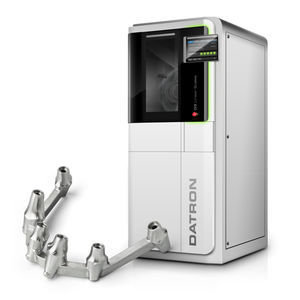

HSC CNC milling machine MXCube3-axisverticalgantry type

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- gantry type

- Machined material

- for aluminum, for non-ferrous metals

- Number of tool stations

- 60 tools

- Other characteristics

- high-speed, high-performance, precision, compact, rigid, HSC, high feed rate

- X travel

1,040 mm

(40.94 in)- Y travel

850 mm

(33.46 in)- Z travel

270 mm

(10.63 in)- Rotational speed

Max.: 34,000 rpm

(213,628 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Power

4 kW, 8 kW

(5.44 hp, 10.88 hp)- Work feed X-axis

40,000 mm/min

(26 in/s)- Work feed Y-axis

40,000 mm/min

(26 in/s)- Work feed Z-axis

28,000 mm/min

(18 in/s)- Weight

3,800 kg

(8,377.57 lb)- Overall length

3,358 mm

(132.2 in)- Overall width

2,058 mm

(81 in)- Overall height

2,235 mm

(88 in)

Description

With the DATRON MXCube performance class, we present the premium segment of our high-speed portal machines!

The DATRON MXCube was especially developed for the execution of demanding HSC strategies and excels not only at removing high volumes of chips but also by achieving an excellent surface finish.

360° Functional Design

Functional Cabin

Excellent access to all functions facilitates operation

Clear visibility of machining

DATRON next

(R)evolutionary DATRON machine control system

Makes HSC milling easy, secure and convenient

Chip Conveyor

External chip conveyor

Transports chips reliable from the working area

Highlights

Automation & handling are part of the basic requirements

Heavy plates or clamping systems can easily be brought into the work area manually or by crane. Integrate an individual automation solution for a process-safe series cycle!

Ergonomics and overview are important

The rugged steel construction in groundbreaking design was made for years of industrial use. Excellent accessibility to all functional elements simplifies operation and maintenance. A large window provides the best view of the machining operation, while the machine status can be seen from a distance thanks to the sharp LED display.

Optimum conditions for HSC milling are a must

Great dynamics, high speeds and feeds, a rigid portal structure, and the resource-saving minimum quantity cooling lubrication enable you to achieve optimum results when machining for example aluminum and non-ferrous metals.

Saving resources also means saving precious space

The DATRON plus: An extraordinarily large work area in relation to the compact footprint.

Catalogs

DATRON MXCube

2 Pages

DATRON_CNC-Machine_Catalogue

64 Pages

Related Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Bridge CNC milling machine

- Precision CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- High-performance CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- Composite CNC milling machine

- CNC milling machine for the automobile industry

- Horizontal CNC milling machine

- 24 tools CNC milling machine

- 30 tools CNC milling machine

- High-speed CNC milling machine

- 60 tools CNC milling machine

- CNC milling machine for the aerospace industry

- Drilling CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.