- Industrial machines and equipment

- Surface Treatment Equipment

- Roller coating machine

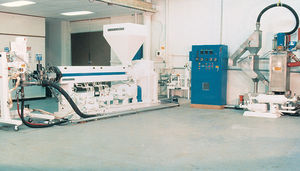

- Davis Standard Extrusion Systems

Roller coating machine for film coatingadhesiveemulsion

Add to favorites

Compare this product

Characteristics

- Options

- roller, adhesive, for film coating, emulsion

- Applications

- high precision

Description

Liquid Coating that Optimizes Efficiency

Davis-Standard’s liquid coating systems are used throughout the world for tapes and labels, silicone-coated products and in specialty coating markets. With more than 50 different standard and custom liquid coating products, we provide profitable solutions for the building and construction, automotive and medical industries.

When it comes to achieving the right viscosity, emulsion, pH and adhesive characteristics for your liquid coating applications, you need a proven and trusted partner. Davis-Standard’s experienced engineers consider multiple variables when building lines for specialty-coated products — ensuring the best solution for your liquid coating specifications.

Regardless if your process demands using film or paper substrates and applying ultra-thin or thick coatings, Davis-Standard’s liquid coating solutions support process improvement and production efficiency in cleanroom environments, slow or high-speed applications, or precision coating and drying technology.

We're constantly asking ourselves what machinery is needed to make the very best tapes and labels? And how do we do it more cost-effectively than anyone else? We know the difference between a good product and a great product: curl-free quality, uniform lamination, and dryness of the end product. We appreciate clear-to-core winding technology that lets you ship right off the winder, as well as no fold-back splicing and zero telescoping during indexing.

That’s why our tape and label experience and capabilities include clean room applications, laminations, low to high-speed applications, and narrow to wide applications.

Catalogs

No catalogs are available for this product.

See all of Davis Standard Extrusion Systems‘s catalogsOther Davis Standard Extrusion Systems products

FLEX PACKAGING | FILMS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.