- Robotics - Automation - Industrial IT

- Automation

- Temperature control system

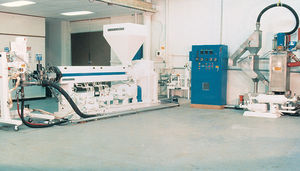

- Davis Standard Extrusion Systems

Quality control system temperatureprocessaccess

Add to favorites

Compare this product

Characteristics

- Function

- process, quality, access, temperature

Description

Flexible and Customized Extrusion Control Solutions for Every Process

The brain of the extruder drives your operation and smarter process controls make a huge impact on the bottom line. That is why every system in Davis-Standard’s full line of process controls is operator-friendly, efficient and reliable. From discrete to full supervisory control, our control systems are engineered in-house to ensure quality and value.

Davis-Standard’s proven systems do the thinking for you about systems integration, temperature control and process controls.

This innovative control system combines total line control and data monitoring into one multi-functional information center. It is specifically designed for high-level converting processes encompassing cast film, blown film, extrusion coating, solvent and aqueous coating and drying. The features are many!

-Provides access to all machine functions including the temperature controller, PLC, and line drives interfaces

-Supervisory control that integrates all converting machine line components into a single user-friendly operator interface, connecting:

Unwinds

Winders

Coaters and dryers

Extruders

Laminators and cast sections

Water recirculation systems

Resin feed and blenders

Web guides

Treaters

Gauges

-Graphics based, operator-friendly touch-screen interface with the keyboard to see the entire process at a glance

-Line run interlocks and diagnostics clearly identified to help the operator get the line running quicker

-Historical data tracking and alarm event logging help in troubleshooting product quality and uniformity problems, as well as tracking machine performance.

Catalogs

No catalogs are available for this product.

See all of Davis Standard Extrusion Systems‘s catalogsOther Davis Standard Extrusion Systems products

FLEX PACKAGING | FILMS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.