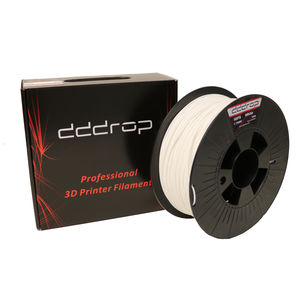

3D printer ABS filament 1,75 mmblueblack

Add to favorites

Compare this product

Characteristics

- Applications

- for 3D printers

- Diameter

- 1,75 mm

- Color

- blue, black, white, green, gray, red, magenta, violet, yellow, orange, brown, pink, beige

- Other characteristics

- impact-resistant, fluorescent, long-life, transparent

- Net weight

1 kg

(2.2 lb)

Description

ABS stands for acrylonitrile butadiene styrene. This material was one of the first plastics that was printed with industrial 3D printers. Now many years later, ABS is still a very popular material, thanks to its low cost and useful mechanical properties. However, it is only reserved for the advanced 3D printer, this is because it has a higher melting temperature (also called glass temperature) and it has to be printed on a heated print bed otherwise warping will occur.

Composition

ABS is made from petroleum products and is therefore a lot less environmentally friendly than PLA. It is not biodegradable and unpleasant fumes are released during printing. Printing with ABS is best done in a ventilated room. All other dddrop filaments are odourless and can be printed next to the coffee maker. Because ABS is a petroleum-based plastic, it is not safe to use it for products that can come into contact with food.

Application

ABS is slightly less strong than PLA and will deform more quickly, but it is much tougher and will not just break. Real durable products can be printed with this. The best-known example is the LEGO block! ABS is also ideal for industrial applications because it can withstand high temperatures, for example it is widely used in the automotive industry for, among other things, dashboards and bumpers.

Tip: always print ABS in a well-ventilated room.

Catalogs

No catalogs are available for this product.

See all of dddrop‘s catalogsRelated Searches

- Additive manufacturing machine

- 3D printer filament

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- FFF 3D printer

- High-speed 3D printer

- PLA filament

- 3D printer PLA filament

- ABS 3D printing machine

- Metal additive manufacturing machine

- Large-format 3D printing machine

- PLA 3D printing machine

- Polyamide 3D printer

- 3D printer PETG filament

- PETG filament

- 3D printer ABS filament

- ABS filament

- Nylon 3D printing machine

- 3D printer Nylon filament

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.