- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

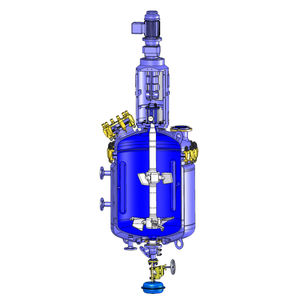

Process reactor laboratoryglass

Add to favorites

Compare this product

Characteristics

- Applications

- process, laboratory

- Material

- glass

Description

De Dietrich Process Systems plans and constructs equipment and plants for the entire field of reaction and thermal separation process engineering. With this experience gained over the years, De Dietrich Process Systems has a comprehensive know-how available in the sector of processing highly aggressive and pure media. The glass reactors convey this knowledge to the user. The solutions shown are fully developed and standardized types of equipment or equipment specifically adapted to a certain process.

High operational reliability and lowest maintenance costs are the outstanding features of glass plants from De Dietrich Process Systems. Our flexible modular construction system with standardized components of borosilicate glass 3.3 allows individual as well as standardized solutions.

In combination with other corrosion resistant materials such as glass lined steel, PTFE, PFA and SiC economical and reliable installations can be realized. The reliable QVF® SUPRA-Line flanges system ensured additional safety and maintenance-free operation. Every installation can be rapidly modified and dismantled if required. All components can be reused without any problem.

Furthermore the material glass offers a unique combination of advantages:

universal corrosion resistance

smooth, nonporous surface reduces deposits and incrustations

catalytic inertness: Reactions remain uninfluenced by the material

physiologically and ecologically safe (100% recycling is possible)

vacuum stability

transparency, enables visual process control

complete emptying

modular design, easily modifiable

Catalogs

No catalogs are available for this product.

See all of De Dietrich‘s catalogsRelated Searches

- Laboratory-scale reactor

- Process reactor

- Pressure reactor

- Bioreactor

- Steel reactor

- Stainless steel reactor

- Reactor for the pharmaceutical industry

- Process bioreactor

- High-pressure reactor

- Glass reactor

- Multipurpose reactor

- Reactor with mixer

- Single-reaction reactor

- Reactor with thermostat

- Glass bioreactor

- Stainless steel bioreactor

- Vacuum reactor

- ATEX reactor

- Supercritical fluid extraction system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.