- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

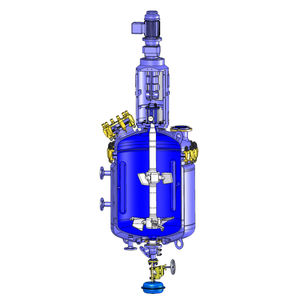

Laboratory distillation unit

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory

Description

Distillation as a thermal separation process is used if the chemical composition of the vapor phase is different from the chemical composition of the liquid phase. This is mostly the case for mixtures of products having different boiling points means different volatilities. Process and plant design to separate, purify, concentrate and recover chemcial components by distillation if one of our core competences.

There are also liquid mixtures forming at a specific ratio a vapor phase with the same composition. These azeotropes and cannot be split further by distillation. If this has nevertheless to be done the process conditions have to be modified so that the composition in the vapor phase becomes different from the liquid phase. This can be realized by e.g. changing the operating pressure or adding another compound. Adding a compound with a low volatility reducing the vapour pressure of one the mixture components lead to a so called extractive distillation as realized e.g. for the QVF® nitric acid and QVF® hydrochloric acid concentration processes.

Another situation occurs if the liquid phase consists of non-miscible liquid components. In that case the vapor pressure of the liquid components are not reduced by each other and the vapor pressure of each liquid phase add up so that the higher boiling component becomes also volatile leading to a e.g.hydro-distillation.

THE BASIC PROCESS STEPS

The distillation process requires an evaporation and a condensation step.

Catalogs

No catalogs are available for this product.

See all of De Dietrich‘s catalogsRelated Searches

- Laboratory-scale reactor

- Process reactor

- Extraction unit

- Automatic distiller

- Water distiller

- Glove box

- Laboratory distiller

- Glass reactor

- Vacuum distiller

- Stainless steel glove box

- Glove box with controllable atmosphere

- Gas receiver

- Containment glove box

- Stainless steel glove box

- Emptying drum glove box

- Glove box for the pharmaceutical industry

- Soxhlet extraction unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.