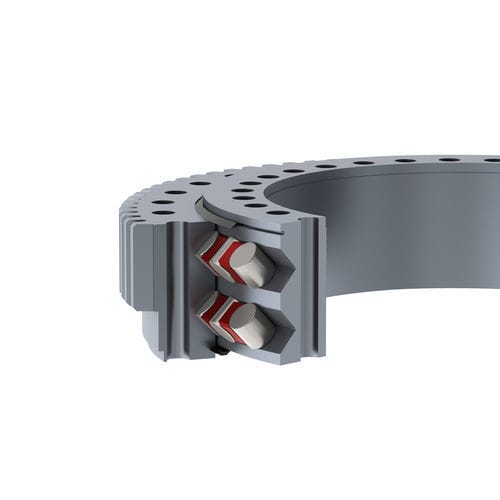

Standard double row crossed rollers slewing rings with external gear with an average raceway diameter from 1,050 to 3,000 mm

Linear contact between the roller and the raceway limits contact pressure and therefore increases service life. The crossed rollers arrangement allows axial and radial loads to be accepted, while ensuring good rigidity of the assembly. It should be noted that the rigidity of the supports is very important in order to guarantee proper operation of the crossed rollers slewing rings.

Double row slewing rings provide greater load capacity in a confined environment.

Ideal for:

Construction: Slewing bearing for crane (high rotation, low rotation, telescopic mobile crane, mobile cable crane, tipper and hook for harbour crane, clamshell crane, grapple crane, magnetic crane, lorry crane, railway crane…), slewing ring for excavators and similar equipments (hydraulic excavator, cable excavator, dragline excavator, concrete pump, coal loader, bulk loader, silo loader…), slewing ring for civil engineering (compactor, vibratory compactor, concrete mixer lorry, orientation drilling rig, drill bit rotation drilling rig, auger drilling rig, concrete mixer…)

Forestry and agriculture: Slewing ring for forestry crane, harvester felling head, shredding machine, grapple skidder, skidder, bogie, trailer coupling, silo unloading screw…

Handling and mining: Slewing ring for fork rotation and wheel’s forklift truck, turntable, turnstile, conveyor system, rotary distributor, vibratory feeder, platform with base rotation, nacelle with top rotation, all-terrain platform, mining machinery, quarrying machinery…